Custom Tool Maker Grows with Rebuilt CNC Grinders

Most shops that manufacture specials, cutting tools that – unlike standard tools – are developed, engineered and ground to uniquely different print specifications or are entirely new designs, are shops that tend to not shy away from a challenge. And for one in particular, it helps to have a talented staff with over 120 years of combined grinding experience paired with the latest CNC cutting tool grinding and software technologies.

That’s the formula that Triple-T Cutting Tools in West Berlin, N.J., has used to grow from its founding in 1995 to becoming a leader in producing custom quality precision cutting tools for the medical, aerospace, firearms and subtractive metal cutting industries in the Northeast.

Triple-T, started by industry veterans, meets the needs of its customers to improve their production efficiency with quality tools that deliver consistent results. Steve Thomas, president of Triple-T Cutting Tools, recalls that the shop purchased a CNC grinder, advertised for work and went on the road – initially targeting the optical market which it knew for carbide and PCD blades. This lead the shop to producing specialty tools.

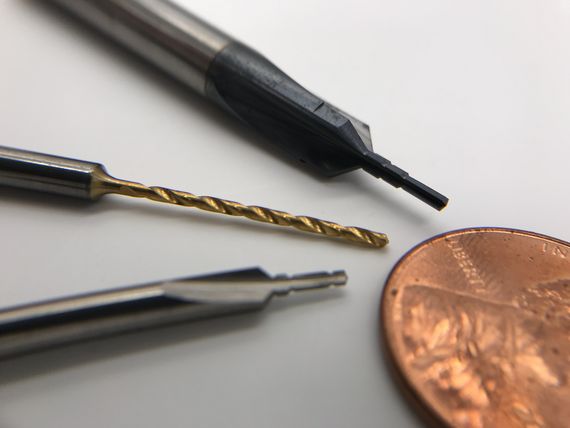

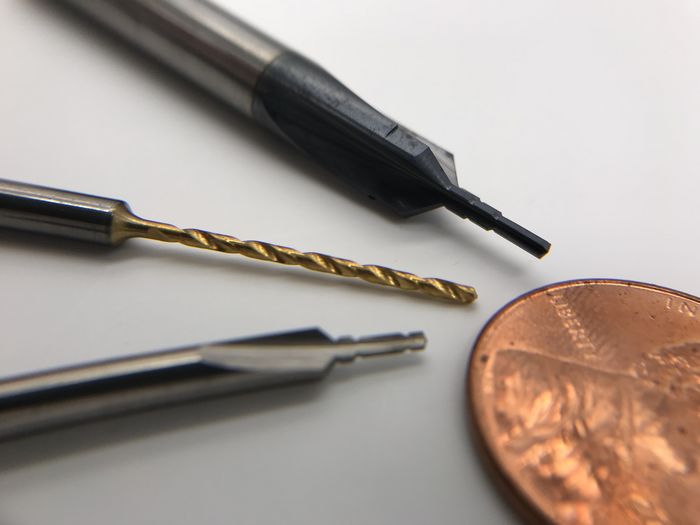

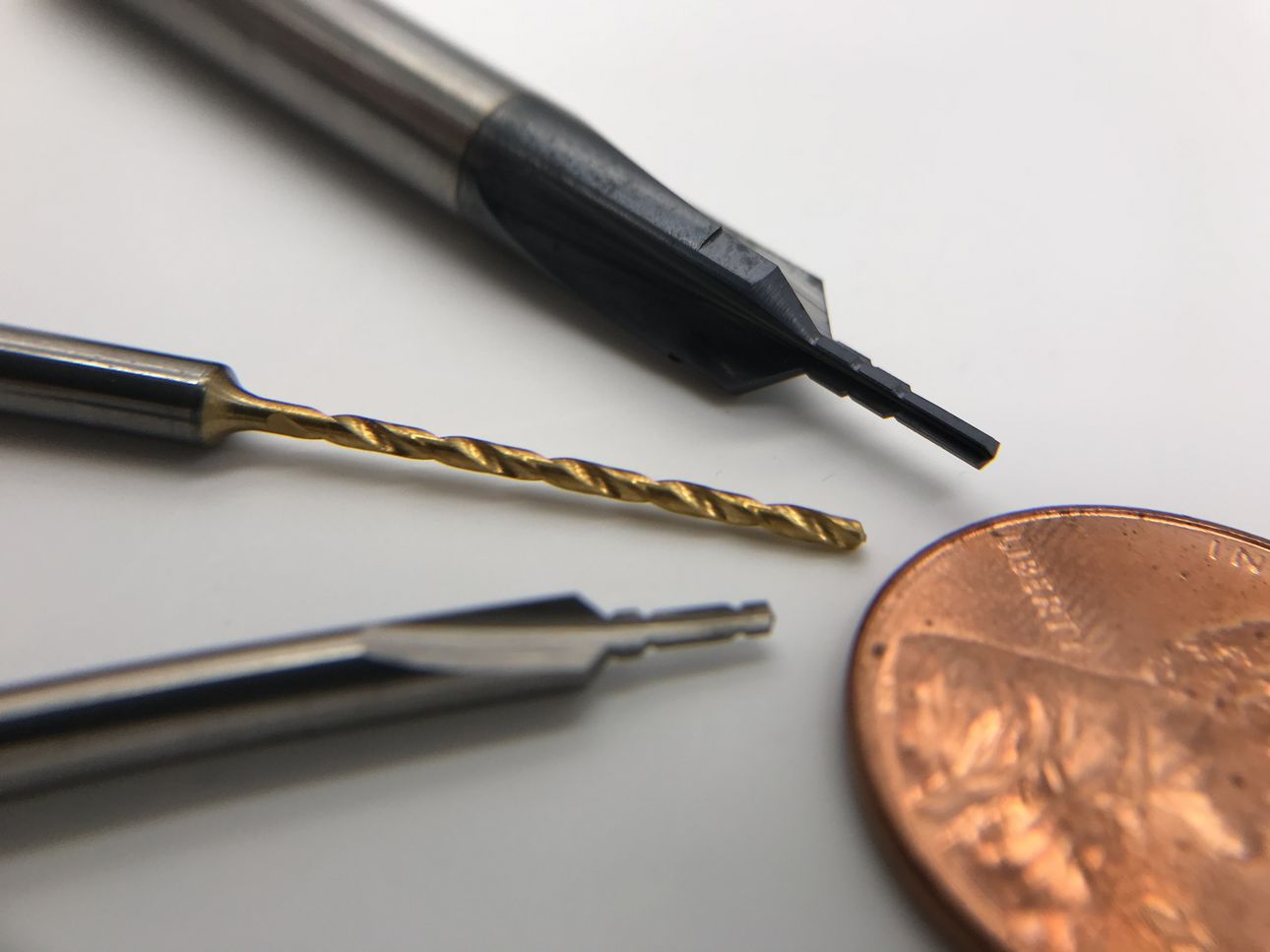

Since then, Triple T’s product offering of metal cutting special tools has grown to include step drills and step reamers, special form tools, corner radius or full radius milling cutters, tapered tools and tapered ball nose tools and thread mills for the blow mold applications, as well as standard end mills and drills.

The shop employs 17 people and runs two shifts with a stable of equipment that has grown to include 10 five-axis grinding machines, two CNC centerless grinders, several conventional grinders. Another 5,000 square feet of space has been added to the facility which is loaded with new equipment.

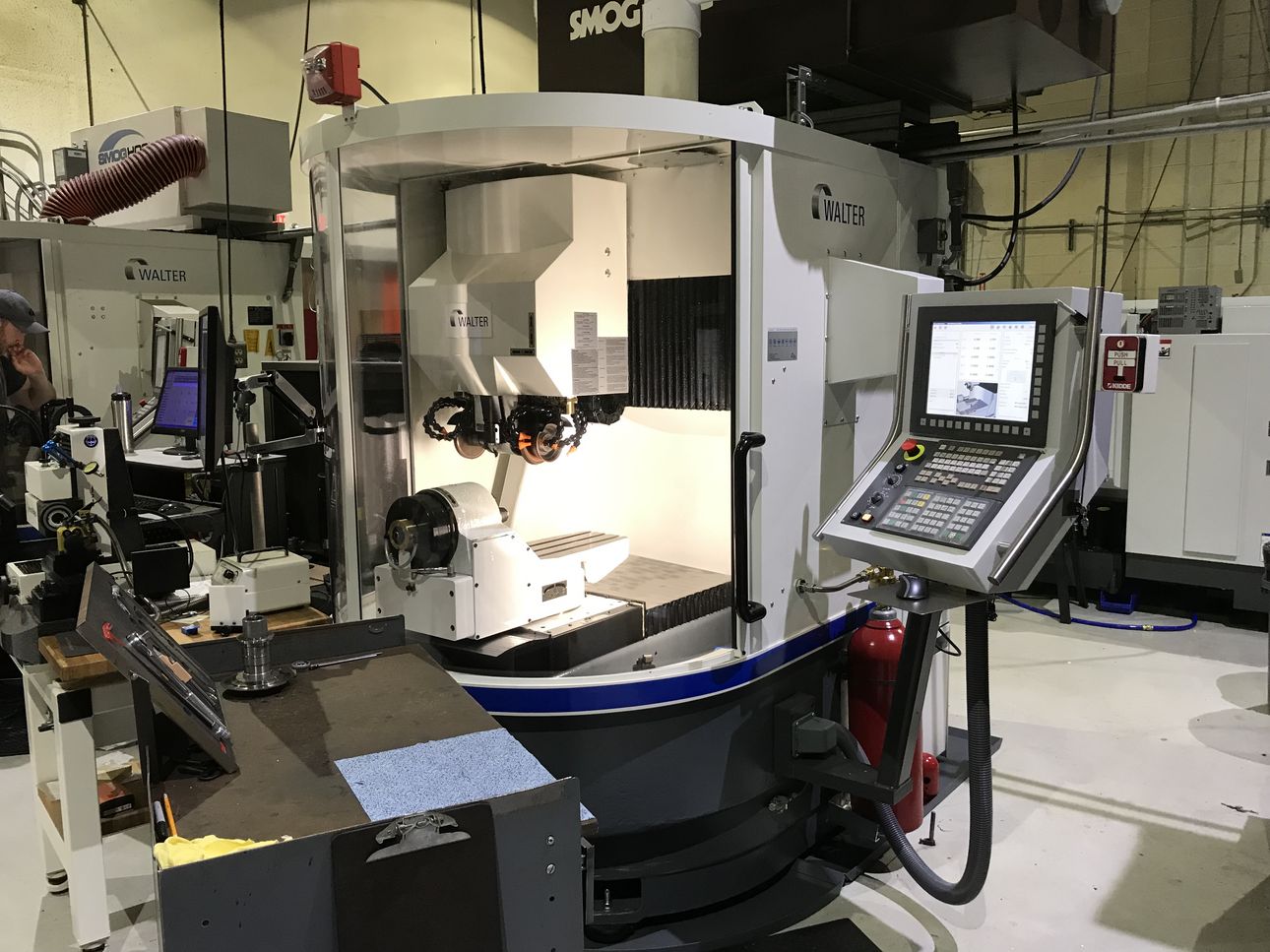

According to Steve Thomas, the complexity of specialty tool grinding takes a talented technician and the right tool grinding machine to determine the best way to make a complex tool. This is why he said that the shop chose rebuilds of WALTER HELITRONIC SL CNC tool grinders with HELITRONIC TOOL STUDIO CAD/CAM software, the same model machine with which he started the company.

Triple-T traded in its first WALTER HELITRONIC SL grinder on a United Grinding North America rebuilt WALTER HELITRONIC SL grinder in 2016 after seeing one demonstrated at IMTS 2016. He then added a second one in 2017.

Why a rebuilt? It’s a question that can be answered in a number of ways for Triple-T. “It’s like having a new machine, but at a significant cost savings,” said Steve’s brother Mike Thomas, vice-president of Triple-T Cutting Tools. “The versatile HELITRONIC TOOL STUDIO CAD/CAM software is convenient for scheduling and makes training our technicians easier. The younger guys can understand the software better, and the latest version of it allows us to not only view the tool but to email that image to our customer for them to twist and turn and view from all angles.”

Steve Thomas explained that a rebuilt machine from United Grinding North America’s Rebuild Department starts with a complete machine disassembly. The only parts of the machine that aren’t new are the base and the shell. Everything else is replaced or renewed, including guideways, all worn parts, and CNC controls. The machine’s geometries are then recommissioned. The crowning addition, he said, is the latest version of the HELITRONIC TOOL STUDIO software.

The powerful software can process all tool parameters from construction through to production. It allows the shop to grind extremely complex geometries in one clamping, essentially turning users into grinding professionals. The interplay between the software and, in this case, rebuilds of Triple-T’s HELITRONIC CNC tool grinders provides quick and seamless design, programming, simulation and production for each special tool production process.

There’s a lot of capability in the software, according to Steve Thomas, who marvels at its power to calculate the complexity of grinding a form on a tool and produce the tool consistently from first piece to last piece.

“Our toughest challenge is to be the best, meet customer requirements and, most importantly, retain them as customers. We do a lot of projects that most other shops shy away from thanks to our expanded capabilities with HELITRONIC TOOL STUDIO and through our own experience, as well as sending our technicians to United Grinding for training. Once I saw the results of what they were able to do after attending that training, I realized it was well worth it,” Steve Thomas admitted.

Being results oriented in grinding precision specials, Triple-T purchases the best grinding wheels available. “We spend a lot of money on superabrasive diamond wheels because they are worth it,” said Steve Thomas said. “They grind fast and cool and last long, but they also need and benefit from the rigidity of grinders like the WALTER HELITRONIC SLs.”

The challenge of developing special form tools is tricky, according to Mike Thomas. “If a customer wants a special form tool for example, we’ll do a combination of multiple standard tools like a step drill with multiple cutters for faster holemaking production by combining the drilling and countersinking operations. We also make all-in-one tools with different sets of flutes and different forms for producing features that could never be done with standard cutting tools,” he said.

Triple-T often has more than 100 cutting tool jobs in production going through the shop every month. Typical lot sizes average between 30 and 50 tools with 90 percent carbide, 10 percent HSS and 95 percent of tools under 1” in diameter.

In addition to Steve and Mike Thomas, the Triple-T team includes Donna Gauntt, director of operations who oversees the day-to-day activities working closely with the company’s customers and staff and Kevin Gauntt, director of technical services, who manages the shop and machinery.

Kevin Gauntt was instrumental in putting the HELITRONIC TOOL STUDIO software and WALTER tool grinders through their paces testing complex jobs and proving out their ability to meet the precision requirements of special tools.

For Triple-T’s business philosophy, teamwork, customer relationships and process improvement go hand in hand. For Steve, Mike and Kevin that teamwork extends to their avocation competing in the Spec Racing Ford (SRF) ACCS class racing series where the three race and sponsor a Champion SRF Race Series. The SRF Series involvement also is a source of business. The company refurbishes hubs for the SRF SCCA class and has hubs in stock ready to ship, as well as supplying custom tooling to performance shops.

To be the best in all its endeavors, Triple-T is committed to investing in the latest technology – that includes rebuilt WALTER HELITRONIC SL tool grinders with HELITRONIC TOOL STUDIO software – to improve its processes and the profitability of its subtractive manufacturing industry customers by supplying the highest quality precision specialty cutting tools.