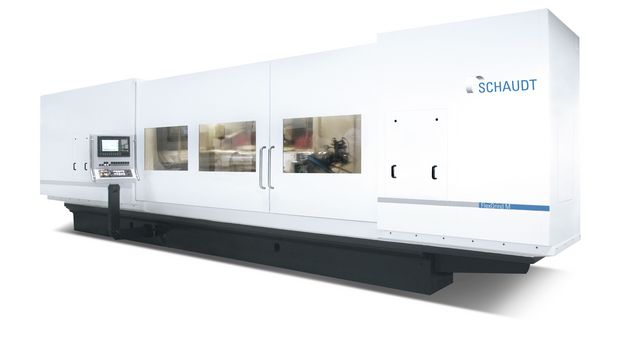

For such parts as aircraft landing gear axle beams, dump truck lifts and automotive crankshafts, precision is key to performance. Manufacturers supplying these components and any other cylindrical parts that require exceptional surface finishes and precision must also produce them at a mass-production pace to meet customer demand.