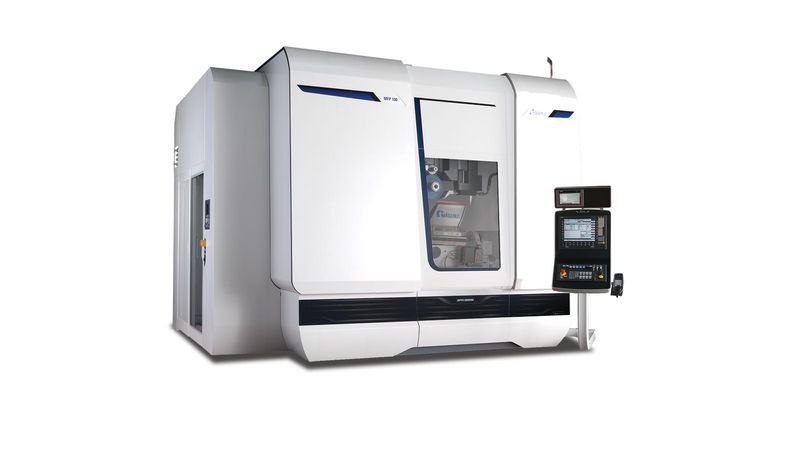

Creep Feed Grinding

The aerospace industry may be leading the way in the use of superalloys and other advanced materials, but as every manufacturer knows, these highly challenging materials are becoming more and more common in other industries as well. To make easy work of these materials – or for any other application requiring significant removal of hard materials – you may consider creep feed grinding, which offers far greater depths of cut and material removal rates comparable to those of milling without sacrificing surface finish quality. Let UNITED GRINDING get you started with machine models powerful enough for this efficiency-boosting part-processing approach.