Cylindrical Grinding Applications

Whether it’s spindle shafts and flange parts, valves and manifolds or electro-hydraulic actuators and turbine vanes, you need speed, precision and dependability to stay ahead of the competition – and meet increasing customer demand for high-precision cylindrical parts.

With the STUDER, SCHAUDT and MIKROSA brands, UNITED GRINDING customers have access to three of the industry’s leading cylindrical grinding brands – along with the applications support, automation solutions and customer service to make that technology work for your shop. See our full range of cylindrical application areas below:

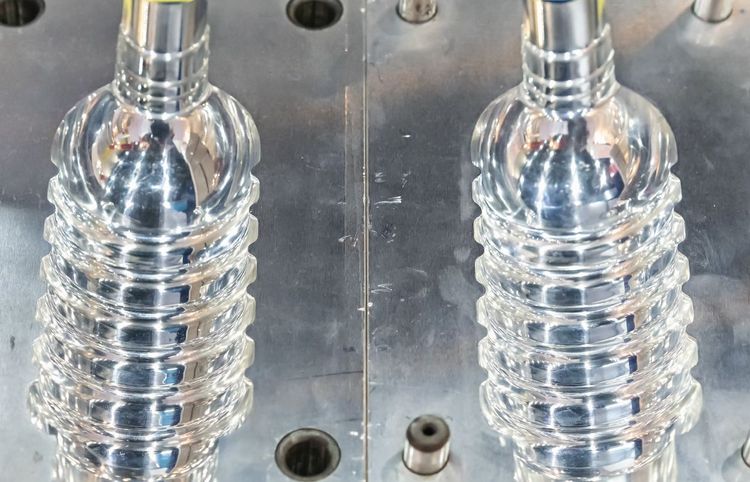

For chuck applications that need the utmost in flexibility and precision – even in high-production environments – our machines offer a comprehensive range of features to help you achieve I.D. grinding success, including machines with and without B axis capabilities.

From manufacturing to aerospace and beyond, our range of universal cylindrical grinding machines have multiple spindles, fully automated B axes and state-of-the-art control technology for universal I.D. grinding.

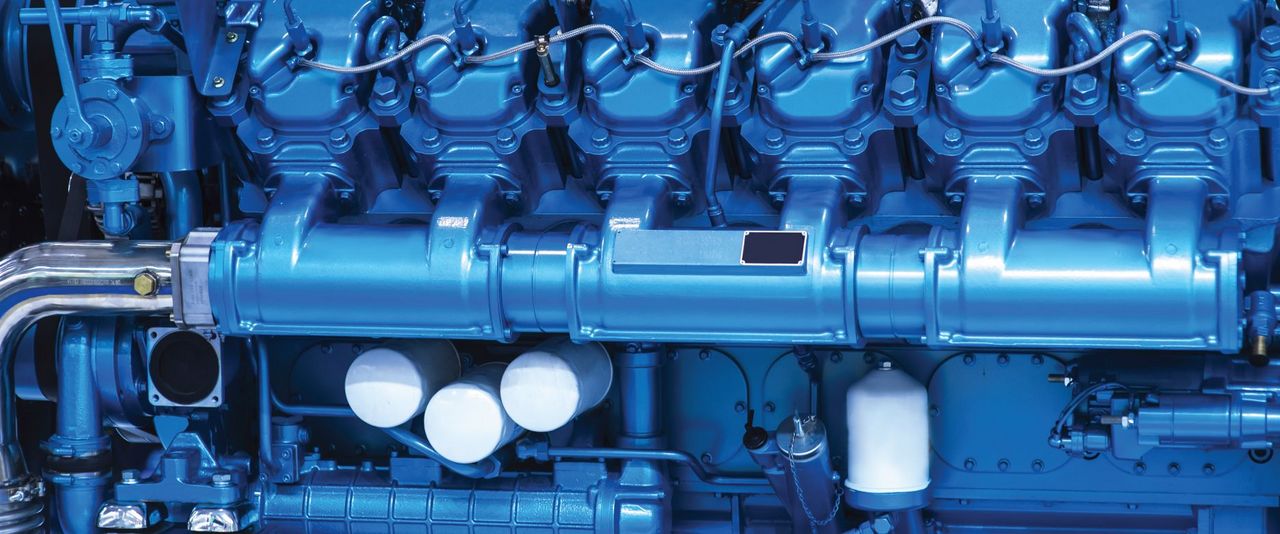

Keeping the automotive industry up and running requires crank and camshafts, along with every other sector that depends on fast production of finely finished shaft-style components. This is why industries turn to STUDER, SCHAUDT and MIKROSA’s powerful O.D. and simultaneous O.D./I.D. production equipment.

For the highest level of precision – and to meet the tight tolerance requirements for hydraulic actuators and other systems found in the world’s most advanced technology – manufacturers need the modular flexibility, fast direct drives and rigid machine bases of our external universal grinding solutions.

Packaging industry dies, axial pump pistons, and hydraulic housings – along with other highly complex workpieces – are now made from the world’s toughest materials, which is why manufacturers turn to UNITED GRINDING for robust cylindrical radius machines with the power to finish the world’s most demanding surfaces.

UNITED GRINDING is your solutions partner, with products and services designed to assist you throughout the life cycle of your CNC grinding machine, including equipment sales, installation, training, applications support, preventive and predictive maintenance, parts and repair services.

If you have a project you'd like to discuss, our team will be happy to assist you.