Shop Grinds Down Tool Inspection Time with New Measuring System

ARCH Cutting Tools- Dayton in Russia, Ohio, a division of ARCH Global Precision, runs 25 high-precision tool-grinding machines 24 hours a day to keep up with customer demand for standard, special or re-sharpened solid-carbide tools. To maintain full speed production requires every facet of the company’s operations to work in harmony. When a growing backlog in the inspection room began to slow production and delay deliveries, the shop sought a solution and found one in a new advanced measurement system and software that together slashed tool inspection times by more than half.

ARCH Dayton employs 40 people and operates out of a 25,000 square-foot facility just across the street from the two-car garage where the grandfather of the company’s current vice president of operations, Doug Voisard, started the shop. The company produces solid-carbide drills and end mills to fill orders that can range from three to 30,000 pieces for customers in the automotive, heating and cooling, orthopedic and other industries. It also manufacturers private label tools and performs regrind services for a few of its larger customers.

“Like his father before him, my dad Eugene Voisard also had a great vision and always made sure we had the latest technology, most of which came from UNITED GRINDING. It was this technology that put us in a great position to keep up with our customers’ demands,” explained Voisard, who joined the family business in 1993.

ARCH Dayton’s relationship with United Grinding unofficially began in the late 1980s when the shop purchased a used WALTER tool-grinding machine. The partnership became official when Doug’s father, the second generation Voisard to own ARCH Dayton, purchased the company’s first new WALTER CNC tool-grinding machine. He was so impressed with WALTER’s commitment to helping him through the learning curve of implementing the advanced technology into the shop and the company’s progressive nature of introducing new technology that he was always first in line to make a purchase when WALTER introduced new machines. As a result, all 25 of the shop’s tool grinders are WALTER machines.

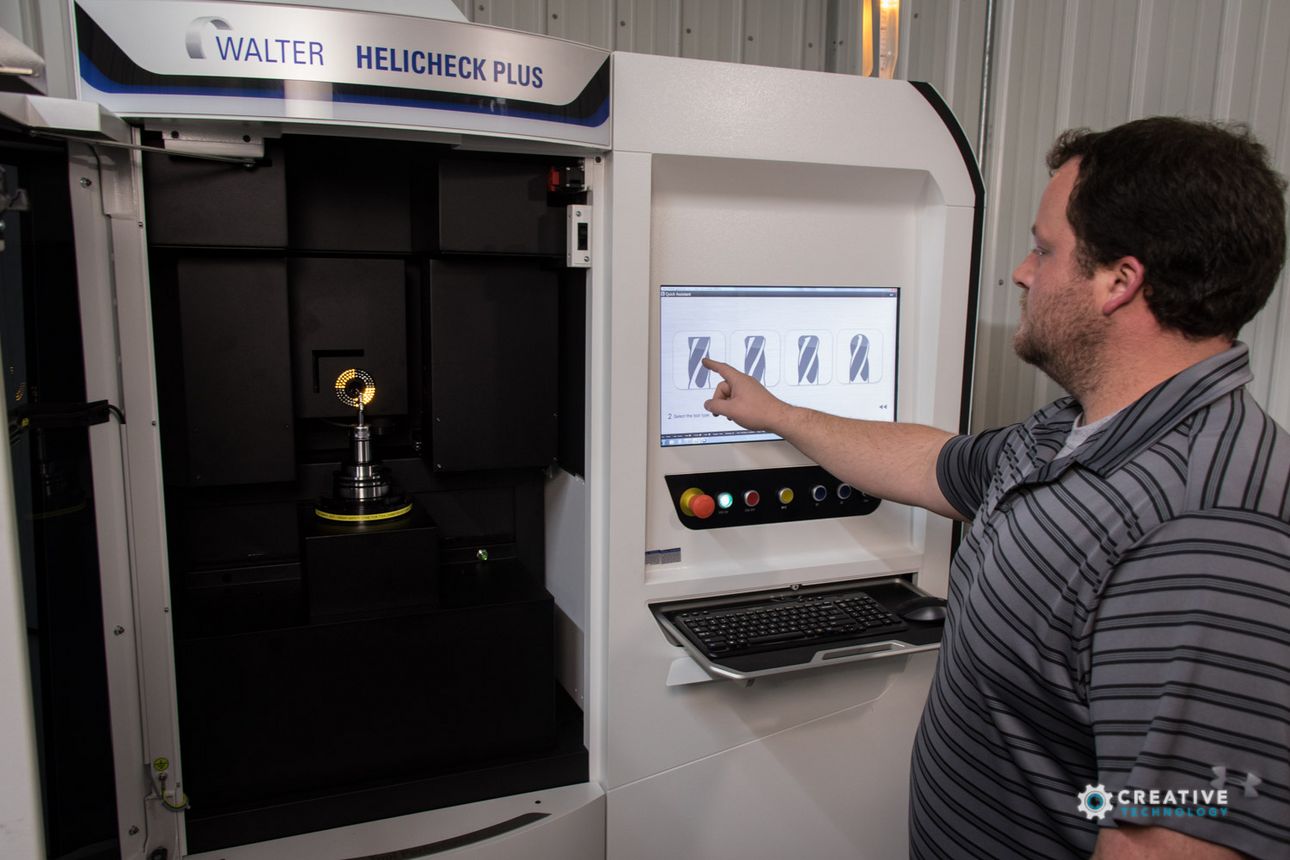

In keeping with its leading-edge technology strategy, ARCH Dayton was one of the first shops in the United States to purchase a WALTER HELICHECK measurement solution. Prior to using HELICHECK, the shop used another type of optical tool inspection machine, one that Voisard described as very “operator opinionated.” According to him, two operators could inspect the same tool and get two different angle measurements by as much as a half or even three quarters of a degree. The HELICHECK solution eliminates operator opinions from the measurement process and results in more accurate measurements.

When Walter came out with the faster, more advanced Helicheck PRO, ARCH Dayton added a second HELICHECK PRO to support and speed operations. The shop uses the system to measure grinding wheels, which speeds set-up time by eliminating the need for the operator to measure each wheel on a separate reflecting type machine with threat of dust and dirt contamination. Now, the system measures each wheel and generates a print out of the accurate measurement, so operators can quickly select the correct wheel.

“The addition of the second measurement system was fantastic. Everyone, from the operators in our shop to our customers, wants their tools checked using the machine because they want to make sure their tools are correct,” said Voisard. “It is so fantastic, in fact, that it created a huge backlog in our inspection room.”

Final inspection rates vary by customer with some requiring 10 percent of the tool order to be inspected, while others expect 100 percent inspection. This inspection volume added to that of the in-process inspections that occurred during each job set up as operators checked and compared tools to a list of required geometries. These two factors combined to overload the HELICHECK machine and created the need to relieve the bottleneck.

Voisard first saw WALTER’s Quick Assistant Software at GrindTec 2016 in Germany where UNITED GRINDING introduced the innovative tool measuring technology. Quick Assistant Software features fully automatic profile detection. It measures tools and detects profiles digitally and automatically with a click of a mouse on WALTER CNC measuring machines eliminating complex and time-consuming preparatory work.

“I was intrigued, but honestly, I thought it was too good to be true,” admitted Voisard. “None of UNITED GRINDING’s competitors were talking about anything like this.”

At the urging of Stefan Krannitz, product specialist for UNITED GRINDING, Voisard made a follow-up trip to UNITED GRINDING to see the software again in early 2017. He took several members of his team and a box of tools to be measured. After seeing how convenient and technically smart the software was, Voisard, with the full support of ARCH leadership, purchased the HELICHECK PLUS machine off the showroom floor.

With QUICK ASSISTANT, an operator uses the simple, graphic interface to complete measurement of cylindrical and conical milling cutters and drills in only three steps. First, the tool family is selected, then the tool type and finally the required measurement parameters.

With the software, operators fully control the machine’s CNC axes electronically on the interface screen during the measurement process. This eliminates the need for manual mechanical movements involving winding a dial or working a joy stick. The software delivers precise, fully automatic and reliable position measurements without operator intervention. Plus, QUICK ASSISTANT copies and makes measurement data available that, in turn, makes measurement of other identical parts just as fast and efficient.

“Before we started using QUICK Assistant software, we had to set up a program for every tool that we wanted to check, which meant the entire checking process could take up to 15 minutes, depending on the number of tool attributes,” explained Voisard. “Now, we simply insert the tool into the machine, and in three clicks we reduce the tool measurement setup time by 50 percent to 75 percent. Now, the entire check time for a common end mill only takes approximately four minutes.”

The addition of the HELICHECK PLUS with QUICK ASSISTANT software has eradicated the inspection room backlog and had a ripple effect throughout the production process. Elimination of long wait times for in-process tool inspection keeps the machines in production. Voisard also credits the new machine and software with faster final inspections as well as with a 10-day overall reduction in delivery times.

Doug Voisard depends on his shop’s partnership with UNITED GRINDING and the WALTER brand that began more than 50 years ago to help him keep up with continued growth and customer demand. He has already ordered another HELITRONIC POWER grinding machine with a loader, and is adding a third robot. Furthermore, he is thrilled that the WALTER brand is now located in UNITED GRINDING’s new North American Headquarters facility in Miamisburg, Ohio, because the close proximity to his shop will make it even easier to stay current on the newest technology and regularly send the company’s machine operators for training.

ARCH Global Precision is a consolidated precision machining services company. ARCH combines the expertise of leading American manufacturers and expanding technologies focusing on manufacturing precision cutting tools and precision machined components for the medical, aerospace & defense and general industrial markets.