CNC Grinding Launches Shop’s Aerospace and Defense Work

A Southampton, Massachusetts, precision machine shop acquired an advanced CNC cylindrical grinder and realized wide-ranging positive effects on work flow and delivery, part quality and machine utilization along with production costs and quoting.

J&E Precision Tool Inc. started in 1979 in a one-stall garage. Initially the shop provided general commercial machining services, including toolmaking and production of firearms parts and fixtures. But, it sought to take on higher-precision work, specifically in the aerospace and defense industry sector.

Participation in the new markets grew from word of mouth, as did J&E’s reputation for consistent on-time delivery of high quality parts. Expanding business produced a need for more manufacturing space and equipment.

In 2001, J&E moved to its current 45,000-sq ft facility and today employs 70 people as well as operates a broad selection of CNC equipment that includes three, four and five-axis milling machines and 10 lathes and a seven-axis milling and turning center. J&E now serves customers across the United States in not only the aerospace and defense markets, but also the microwave equipment industry – a niche market that, according to Jon Labrie, general manager at J&E Precision Tool, “has been growing like wildfire” for the shop.

With new markets and customers came the demand for increasingly more complex and even higher precision parts. “Anybody can make the easy stuff,” Labrie said. “Customer engineers continue to push the design and manufacturability limits, and we embrace the challenge. We have a great group of people here who are really smart.”

Advanced manufacturing systems also help J&E meet such challenges and fulfill customer requirements. “We try to stay on top of the curve as far as technology goes,” said Labrie. “We have the latest and greatest on the floor, whether it is for programming or machining or tooling. We are quite willing to spend capital on equipment, and make the right moves to keep our customers happy.”

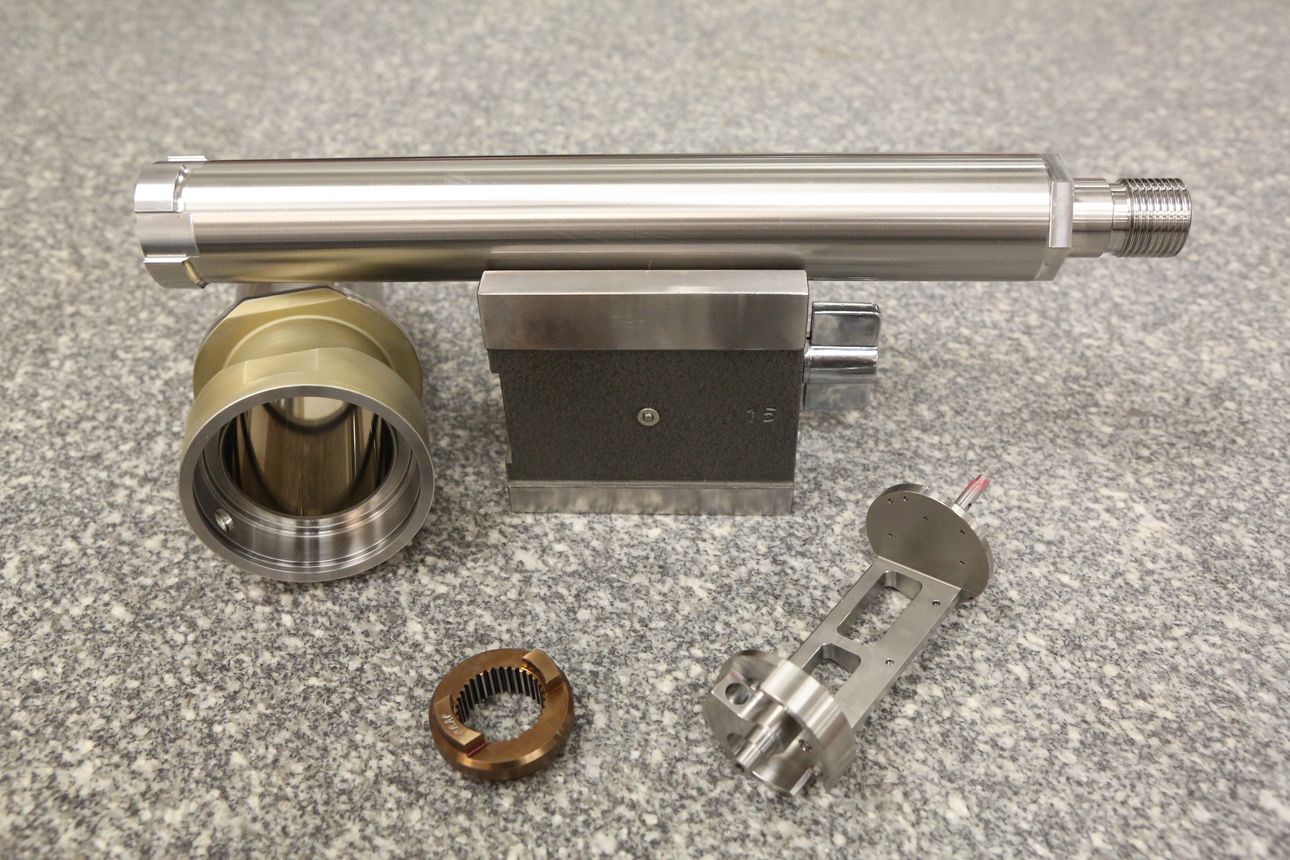

It was with customer needs in mind that the shop recently added advanced CNC grinding capability to maximize flexibility, precision and job turnaround speed. Previously, grinding capability at the shop was limited to OD, ID and flat grinding and some lapping, on machines that were “old relics,” according to Labrie. They were incapable of any real production work, so J&E subcontracted out its production grinding. However, issues with cost and scheduling constantly arose.

“We manufacture parts from beginning to end, from raw stock to finished parts. We could no longer depend on someone else to grind parts to the schedule we needed,” said Labrie. “We were at the mercy of our supplier. He did a fantastic job but had many other customers also vying for his time. This is when we acquired a CNC grinder to eliminate a lot of those problems, and it did.”

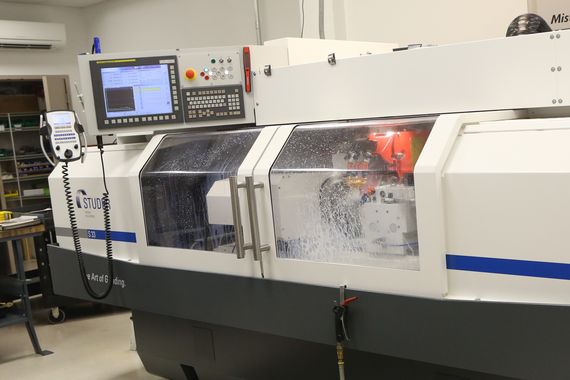

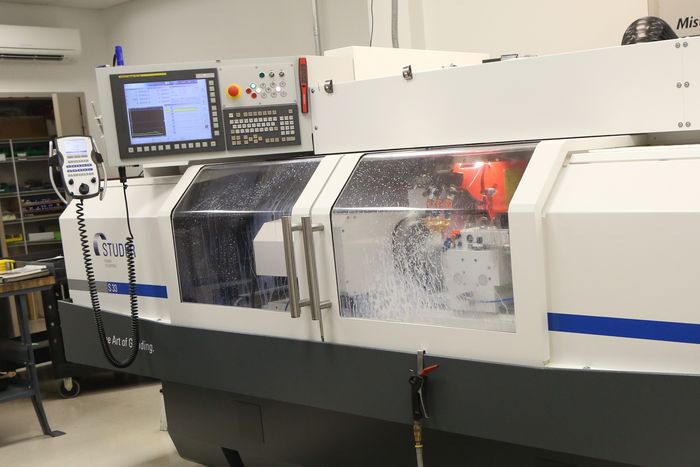

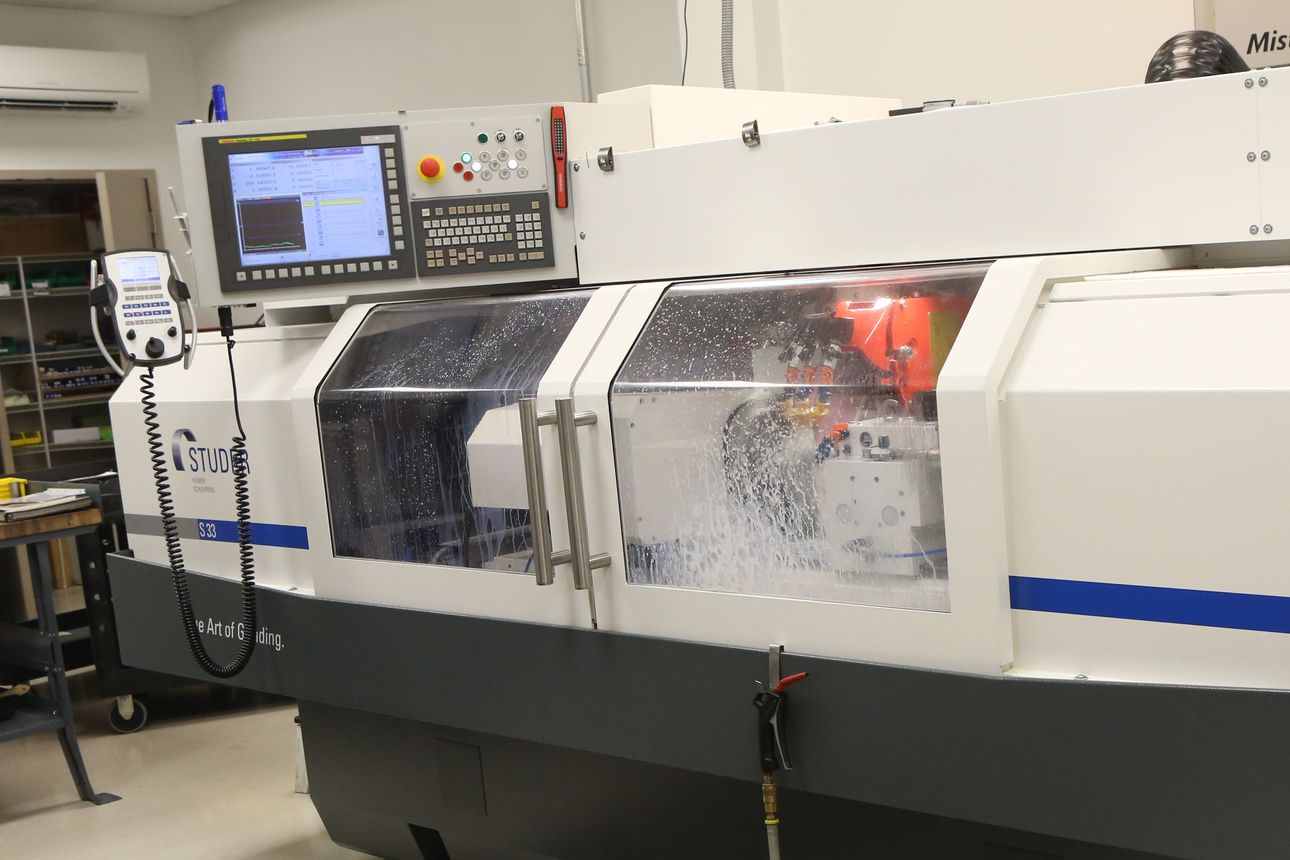

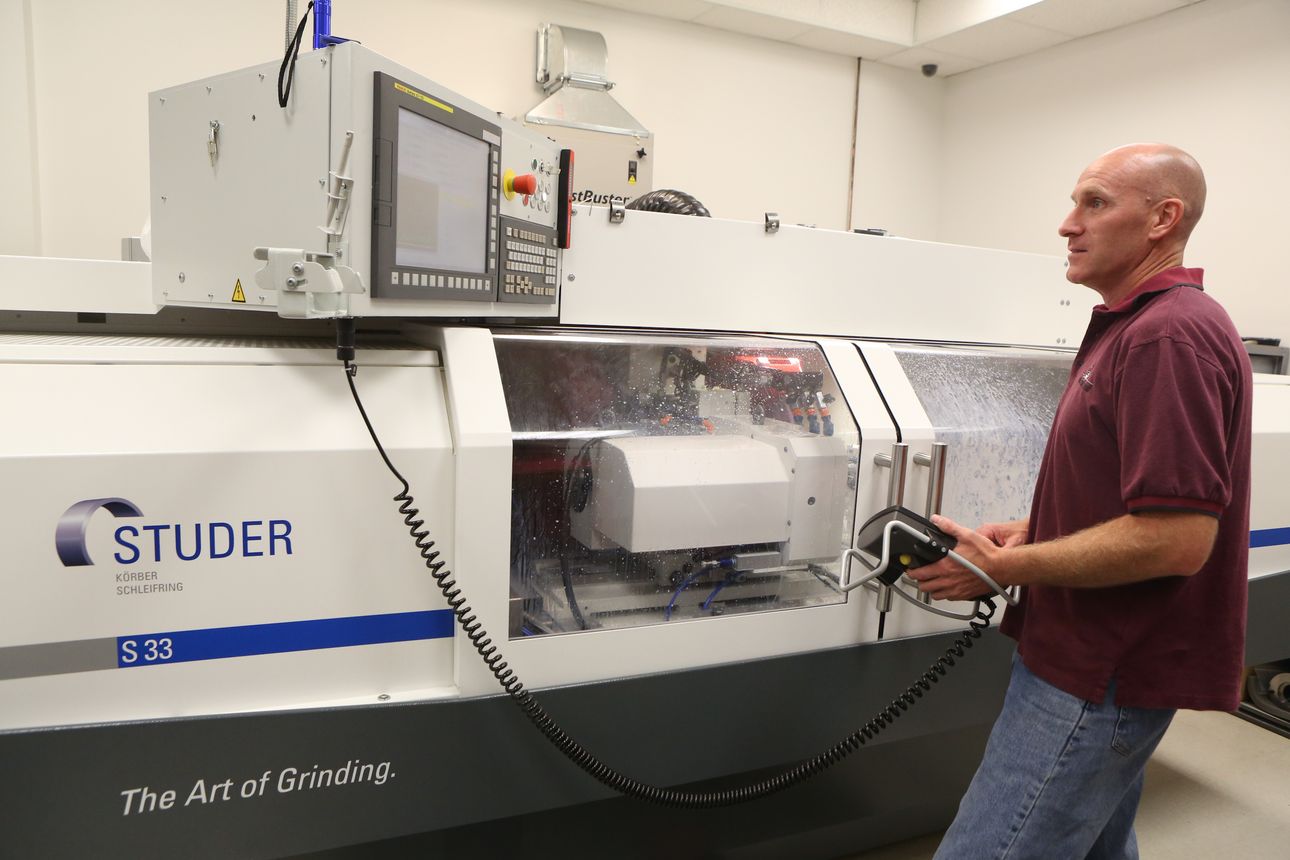

After thoroughly researching available grinding technology, J&E purchased a Studer S33 CNC universal cylindrical grinder from United Grinding in mid-2013. The S33 processes medium-sized workpieces in individual and batch production and features one ID wheel and two OD wheels. Its wheelhead has two motor spindles for external grinding as well as an internal grinding attachment, which allows J&E to grind complex workpieces in single clampings.

United Grinding helped J&E get up to speed quickly with the new machine. “They came into our facility and trained us for a week up front,” Labrie said. “Then, after we ran the machine for a while, they came back for another week once we knew more about what we were doing and had more questions.”

With the acquisition of the Studer grinder, J&E regained full control of its grinding process. “If I want to put two shifts on a part, I can, if I want to run over the weekend, the machine will. That is huge when it comes to delivery,” Labrie said. “And, we no longer subcontract out our grinding work.”

Use of the S33 grinder also enhances the shop’s ability to maintain top part quality. Previously, some parts were both roughed and finished on turning centers. Now, many of those same parts are roughed on a turning center and finished on the grinder.

“Not only are we getting a higher quality parts, we are getting them done faster as well,” said Labrie. “Plus, replacing turning with grinding frees up our turning centers to process other parts.”

From its work on aerospace and defense projects, J&E is familiar with machining of high-performance materials such as stainless steels, titaniums, nickel base alloys and aluminum. But what takes the shop to the next level, according to Labrie, is grinding those materials.

When grinding exotic materials, he explained, choices of wheel types, speeds and feeds and cutting fluids can make a significant difference in final part dimensions and quality. The shop occasionally resorts to trial and error to find optimal grinding parameters, but the grinding knowledge and experience of staff personnel usually produce the best combinations of tooling and parameters. The machine’s operators also program the shop’s grinding processes.

Creating effective grinding setups is another challenge. Labrie said that setups occasionally involve “crazy stuff and other unique fixtures” to hold parts because not all of them are round and simple to clamp.

“With tight tolerances you don’t want to squeeze a thin-walled part out of round, or push the process too hard, or add stresses during grinding,” he advised. “And fixturing is often the determining factor of whether or not a part is acceptable once grinding is complete.”

Grinding parts in house instead of subcontracting the work positively affects the quoting process at J&E. Labrie pointed out that quotes previously took into account the subcontractor’s grinding charge, which included the subcontractor’s overhead costs and profit margin. Now, with the grinding performed in-house, those outside costs are eliminated, and in turn, J&E can offer customers more competitive pricing. The Studer grinder also enables the shop to take on jobs it would have had to turn down in the past.

J&E produces some parts small enough to require a microscope for inspection. “We’ve drilled holes down to 0.0005" in diameter, and we’ve run end mills measuring just under 0.0008" in diameter,” said Labrie. At the same time, the shop also machines parts as large as 20" x 60" x 18". Job lot sizes range from one to upwards of 2,500 pieces. And at any given time, J&E can have a hundred jobs being processed simultaneously.

Adding flexible CNC grinding technology has affected nearly every aspect of J&E’s production process. Grinding capability and process control has facilitated the addition of new markets and customers, higher part quality and reliable delivery times, and lower costs. Labrie expects the progress to continue; “We never stop looking forward,” he said.