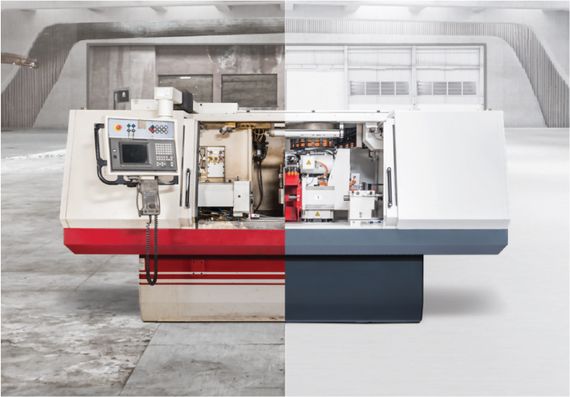

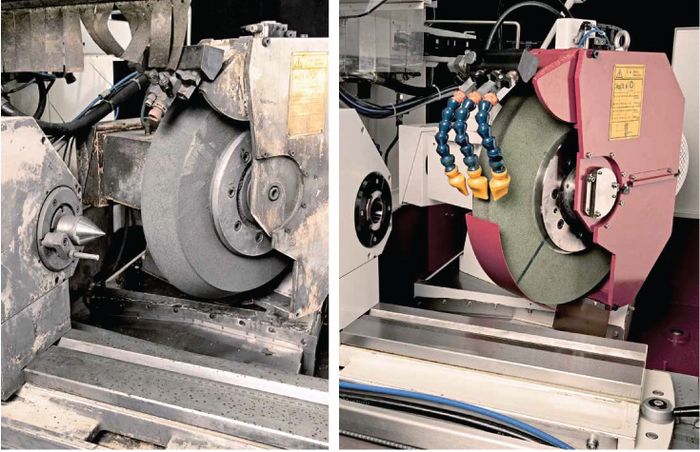

When is it time for a grinding machine tool rebuild?

Repairs and rebuilds are a great way to get like-new performance from your well-used grinding machine tool. At UNITED GRINDING North America, we use only OEM parts to ensure the finest rebuild possible. It starts with an on-site evaluation of your machine to take inventory of its requirements and to note your future needs.

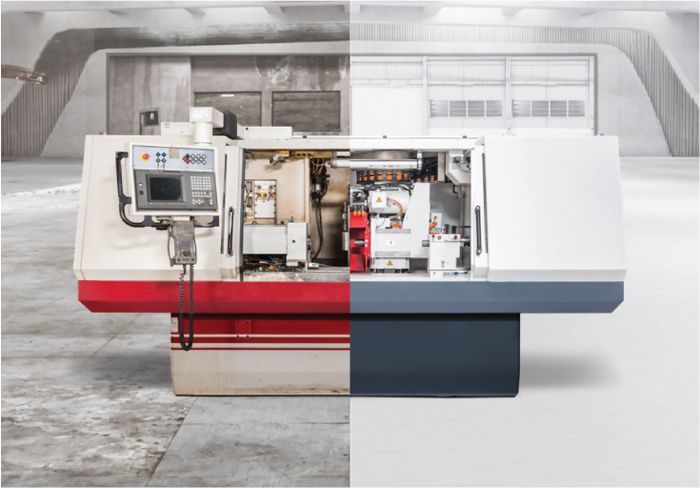

A machine rebuild includes:

- Complete machine disassembly

- Guideway renewal

- Freshly repainted enclosures and components

- Evaluation of the machine and its geometry

- Replacement of all worn parts

- Recommissioned geometry

During the overhaul, we make every effort to provide you with a loaner machine.

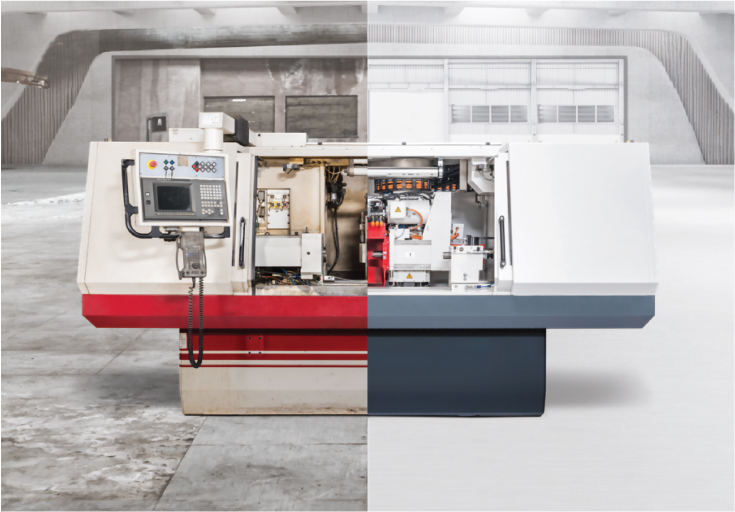

Benefits of a grinding machine tool rebuild

Our repair and rebuild service brings a long list of benefits, including:

- Full one-year warranty on all service and parts

- Precision and productivity that’s comparable to a new machine

- Employees can resume operations on familiar equipment

We can perform some forms of mechanical and electrical service, including some retrofits, while your equipment remains at your shop. Talk to us to determine the best approach to your equipment needs.

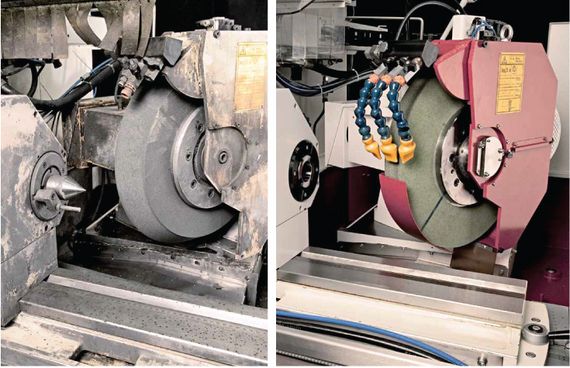

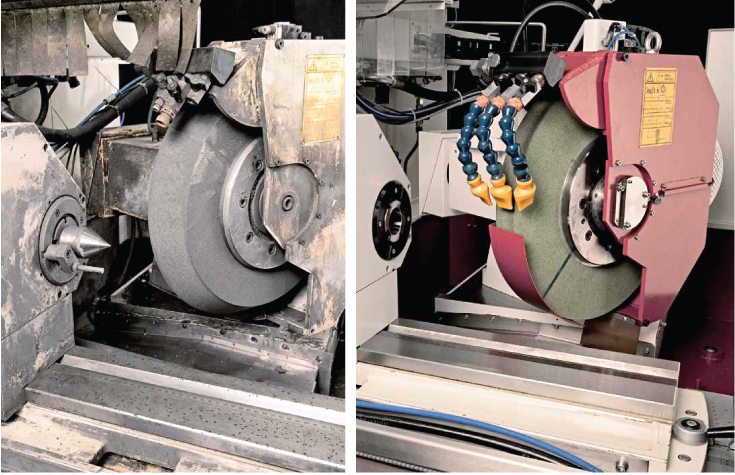

Grinding machine tool assembly overhaul

We analyze the assembly in detail and prepare an estimate for the overhaul, tailored to your requirements. An assembly overhaul comprises:

- Functional and geometry inspection

- Construction of the assembly and geometry

- Repainting of the components

If required, we can undertake conversion and retrofitting of options for you and commission the machine at your premises. Naturally, you will also benefit from a warranty on all work carried out.

The advantages of an assembly overhaul

- An assembly that's as good as new

- Extended service life of the machine

- Rectification of geometry problems