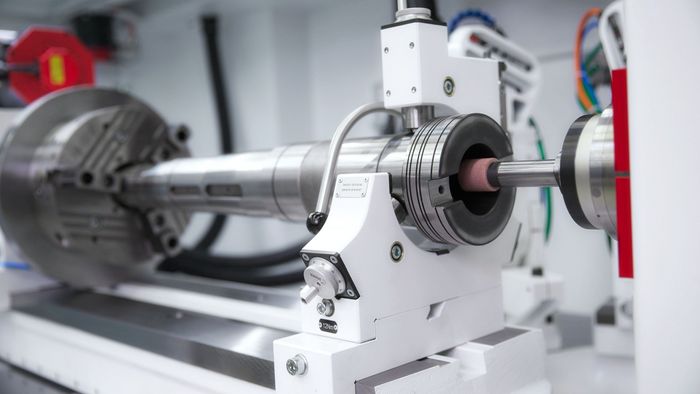

The universal machines for

a broad range of internal

cylindrical grinding applications.

Basic Data

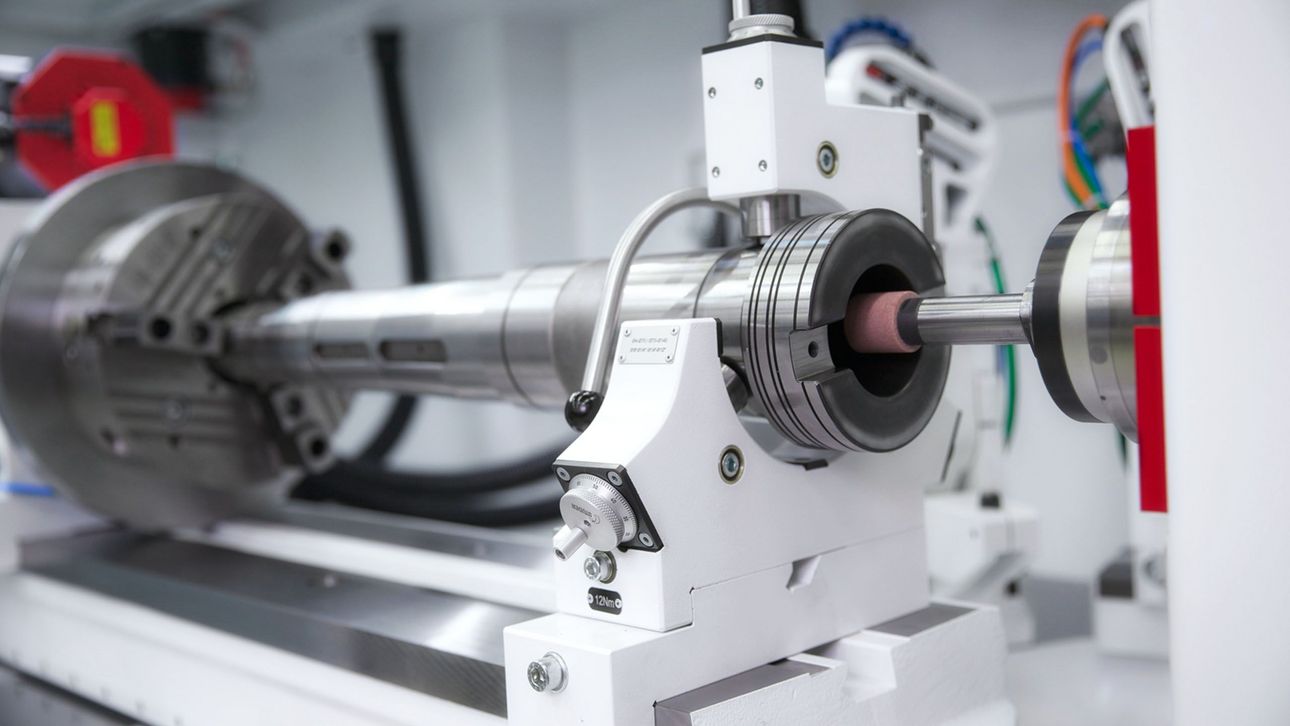

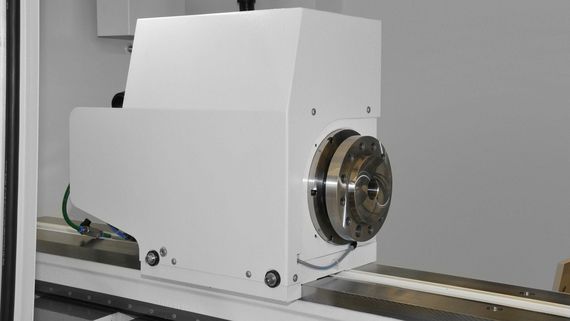

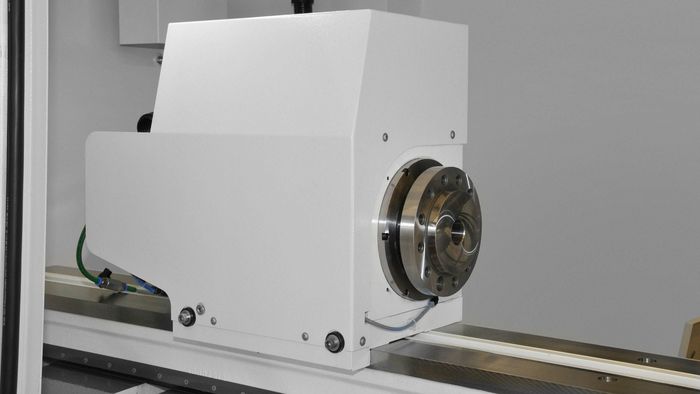

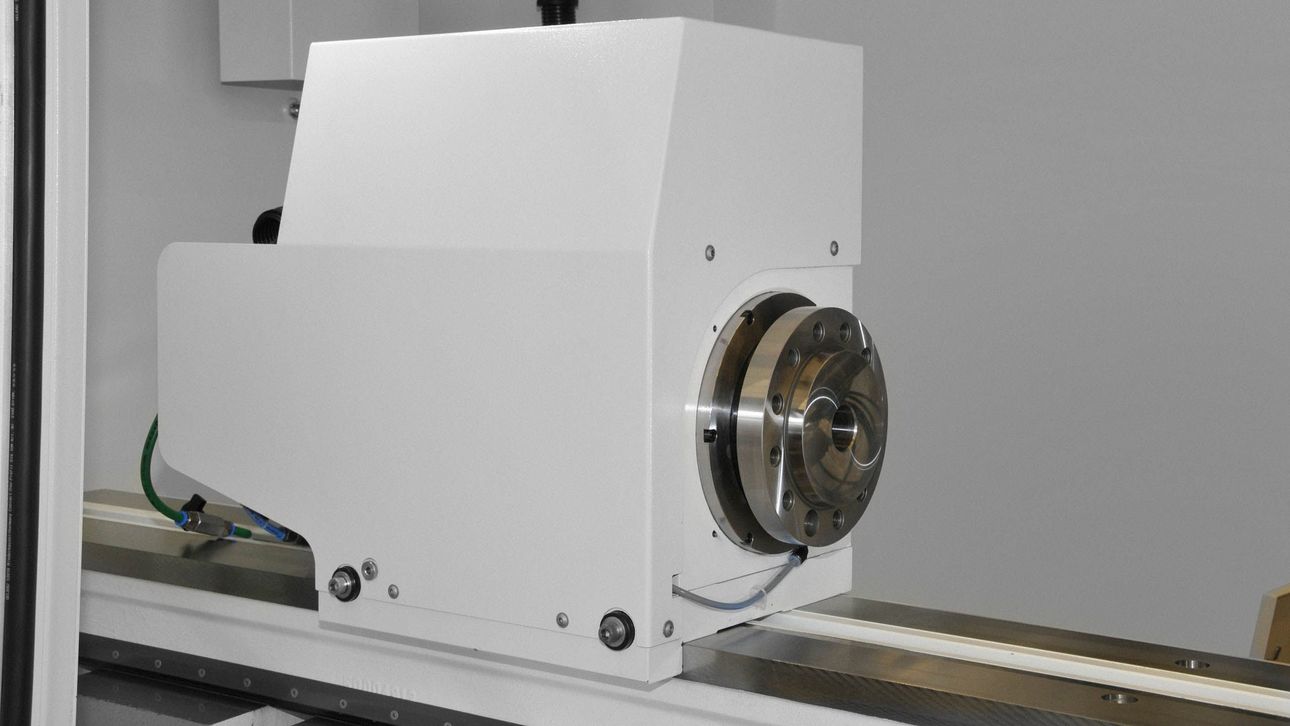

The S151 is a CNC universal internal cylindrical grinding machine of the latest generation. It is available in two sizes, for workpiece lengths (including clamping device) up to 700mm (27.5") or 1300mm (51.2"). The swing diameter above the workpiece table is 550mm (21.6").

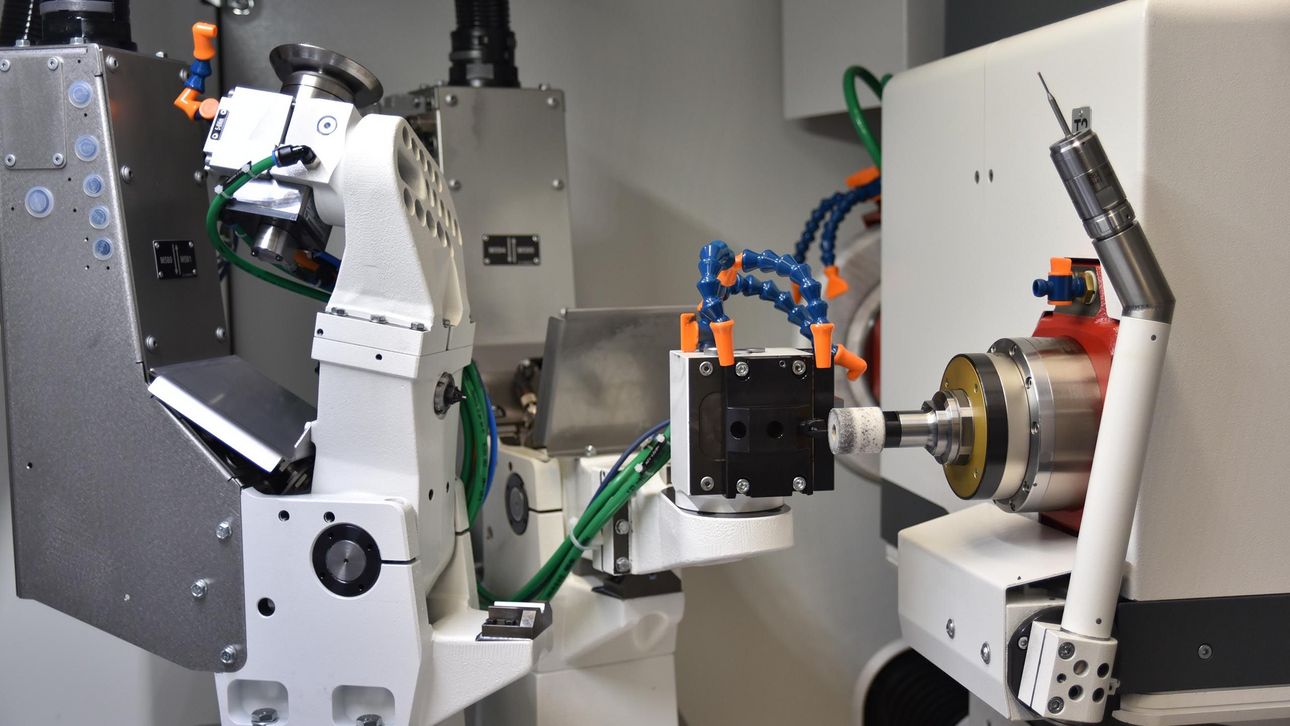

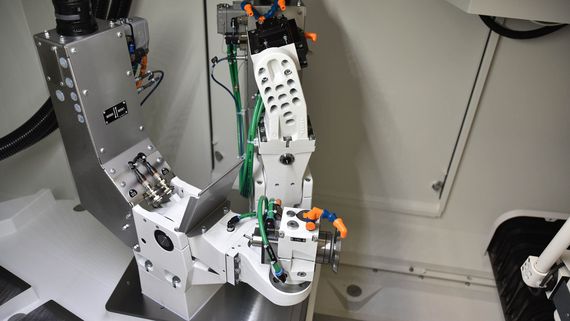

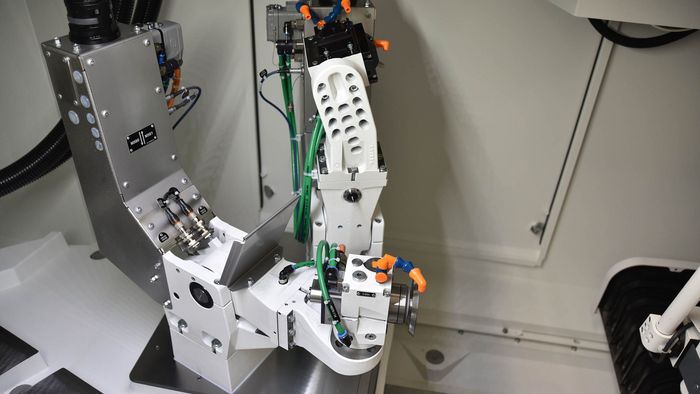

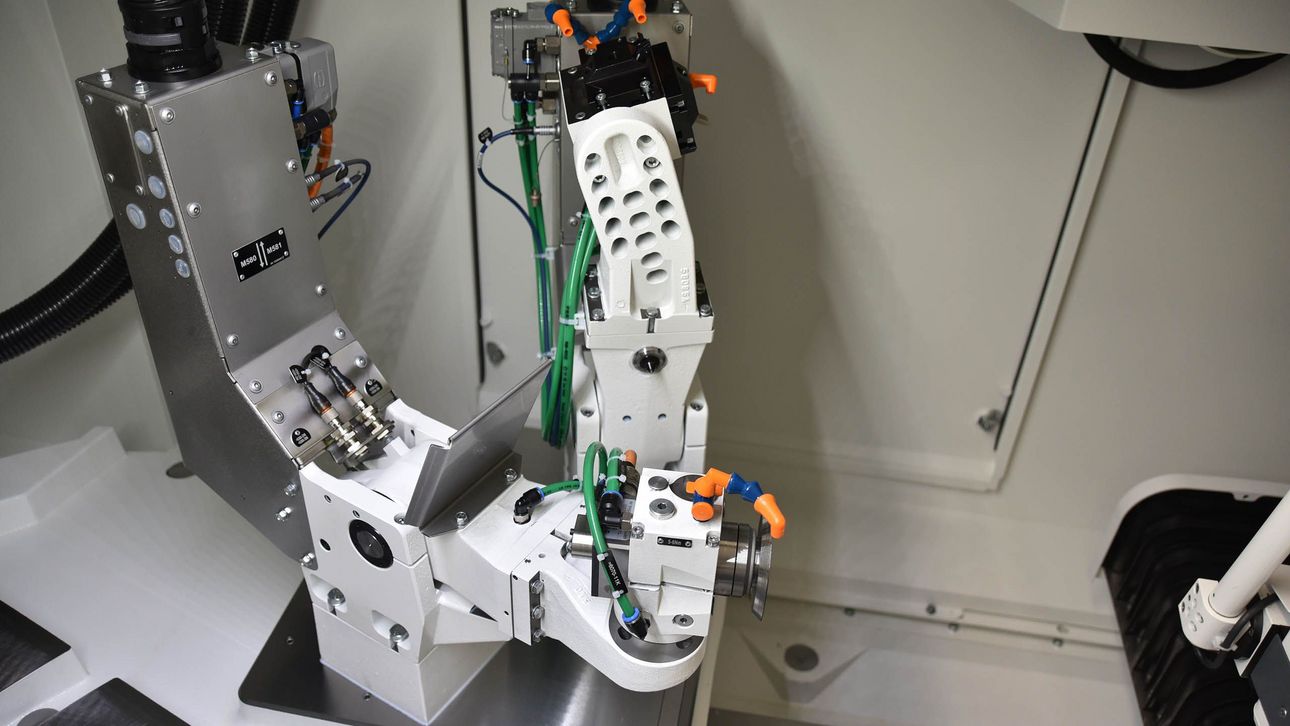

It is primarily used for machining large spindle shafts, spindle housings, rotor shafts or large flange parts. The S151 has a host of sophisticated technical features such as the revolutionary StuderGuide® guideway system, high-precision axis drives with linear motors, extremely fast direct drive of the grinding spindle turret, automatic swiveling of the workpiece table etc.

Images

Hardware / Software

Hardware:

- StuderGuide® guide system with linear drive

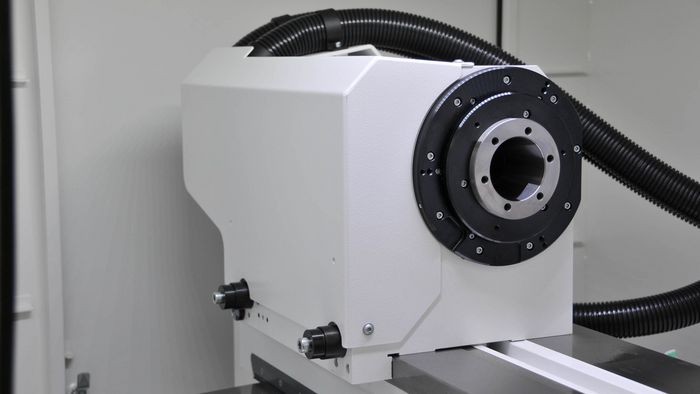

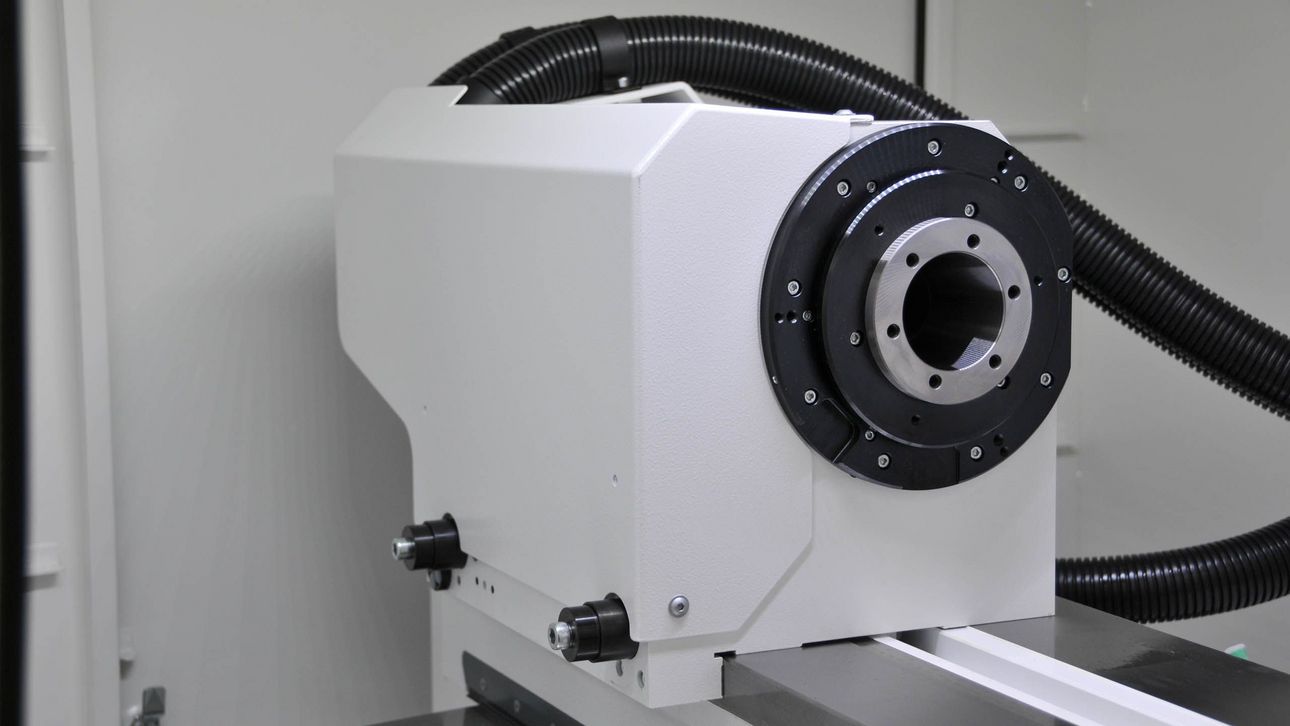

- Grinding spindle turret with up to four grinding spindles

- Automatically swiveling workpiece table

- C-axis for workhead spindle for form and thread grinding

- Full enclosure with two sliding doors

- Granitan® S103 mineral casting machine base

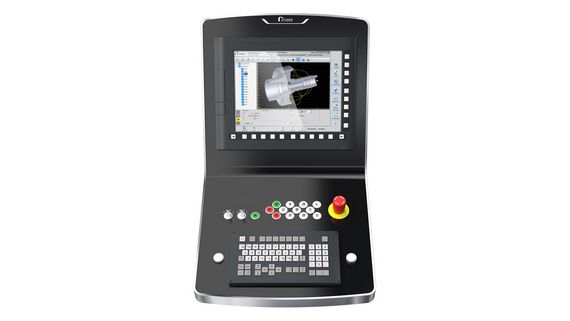

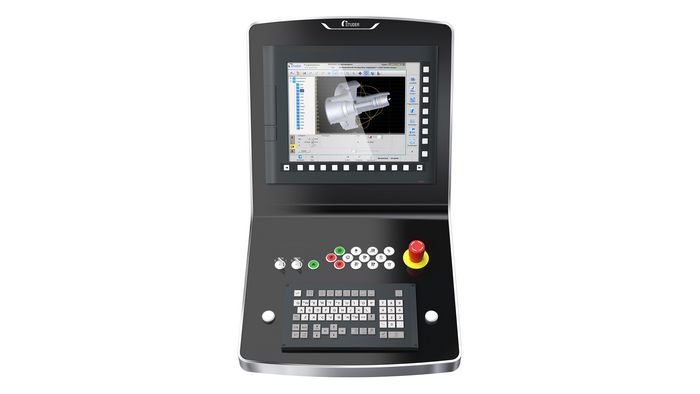

- C.O.R.E. Panel

Software:

- C.O.R.E. OS operating system

- Very simple operation and programming thanks to StuderWIN

- Short setup and resetting times e.g. with STUDER Quick-Set

- Standardized interfaces for loader and peripheral devices

Technical Data

Linear Axes

Max. Travel X

500 mm

Max. Travel Speed X

20'000 mm/min

Max. Travel Z

500 mm

Max. Travel Speed Z

20'000 mm/min

Spindle drive

Max. Spindle Power

18 kW

Max. Number Of Revolutions

120'000 /min

Max. Grinding Wheel Diameter

300 mm

Max. Grinding Wheel Width

32 mm

Swiveling Axes

Swiveling Range B

330 °

Swiveling Range C

∞ °

Workpiece Data

Workpiece Length

700 mm

Workpiece Diameter

550 mm

Max. Workpiece Weight

250 kg

Center Height

275 mm

Linear Axes

Max. Travel X

500 mm

Max. Travel Speed X

20'000 mm/min

Max. Travel Z

700 mm

Max. Travel Speed Z

20'000 mm/min

Spindle drive

Max. Spindle Power

18 kW

Max. Number Of Revolutions

120'000 /min

Max. Grinding Wheel Diameter

300 mm

Max. Grinding Wheel Width

32 mm

Swiveling Axes

Swiveling Range B

330 °

Swiveling Range C

∞ °

Workpiece Data

Workpiece Length

1'300 mm

Workpiece Diameter

550 mm

Max. Workpiece Weight

250 kg

Center Height

275 mm