Empowering Customers with New Solutions in 2026 and Beyond

Connecting the Dots in Your Shop

Because minimal manpower is the new normal on many manufacturing shop floors, efficiency and automation is often the priority. Therefore, UNITED GRINDING has built a new Customer Portal using the Transaction-Network platform, offering a digital interface that grants 24/7 access to important information and capabilities designed to reduce downtime and streamline service.

One key feature of the new portal includes access to machine model-specific spare parts catalogs that allow customers to place spare parts orders, view pricing, availability, and delivery times. Additionally, users of the new Customer Portal will be able to send machine service tickets directly to the Customer Care team and receive notifications for updates on offers, orders, service requests, and more.

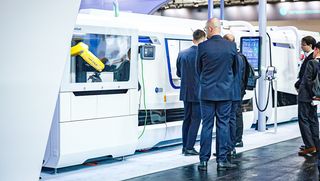

Automation Made Easy

Interested in automating your manufacturing process? WALTER’s automated solution for connecting their grinding, measuring and eroding machines is coming to the North American market in 2026. Automated Tool Production (ATP) is a single automation system for complete tool production that includes a specialized ATP ROBOCELL for loading and unloading blanks and finished parts as well as the ATP AMR, a mobile transport robot for workpiece logistics. The system delivers complete closed-loop processes from machining to measuring and includes a warehousing module for inventory management.

ATP ROBOCELL is front accessible with three access gates and buffer stations for production without downtime and requires no additional floor space when compared to a traditional robot loader.

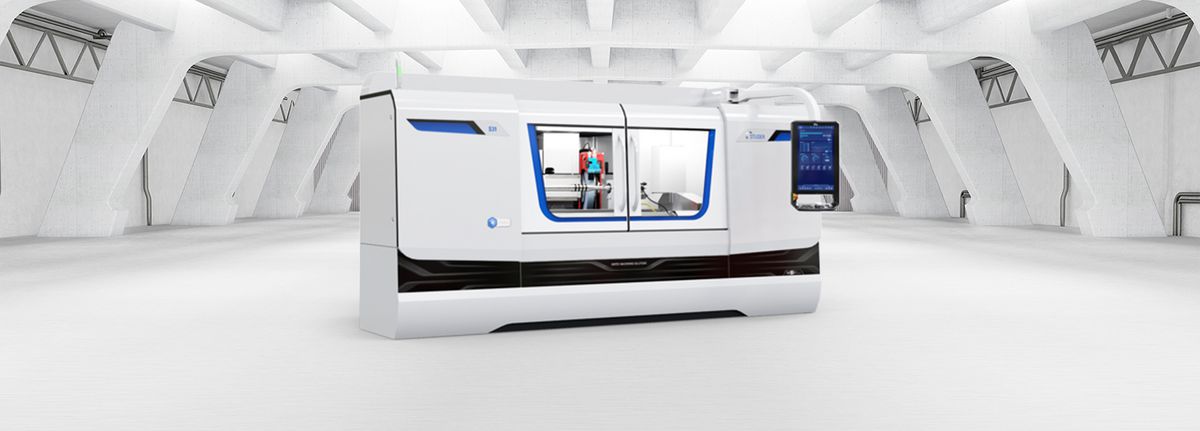

Customize, Extend and Dress Less

To remain competitive, it’s crucial to implement the latest grinding machine that can solve any grinding challenge. The STUDER S31 universal grinding machine, an EMO show-stopper, enables manufacturers to grind different diameters and any taper with only one grinding wheel and without time-consuming intermediate wheel dressing.

This S31 was equipped with a traveling tailstock, which can be programmed to adjust center distances to accommodate workpieces with varying lengths. It offers an extended range of distances between centers – 400 mm and 1,600 mm. The Granitan® machine base on the S31 and several other STUDER models feature integrated coolant channels, delivering supreme thermal stability as well as the vibration damping effects Granitan has become known for.

The S31 also touts an extended X-axis stroke of 370 mm (14.5") that enables a variety of wheelhead variants that can be customized, including the choice between the turret wheelhead with an infinite B-axis or a B-axis with a 1° Hirth coupling.

The Daily Grind, Perfected

If finding cylindrical grinding (OD/ID grinding) solutions is your goal for the upcoming year, STUDER has an entire line of the most advanced machines and systems for any grinding job. The following is a list of some available options:

- Entry-level cylindrical grinding with automation: The STUDER favoritCNC is now available with an automation interface that integrates machine tending automation cells directly into the machine’s interface.

- ID-radius CNC grinding: The STUDER S131r, especially suited for the die industry, contains a swiveling B-axis, which enables the machine to perfectly blend the radius from the ID of the workpiece to the face while achieving extremely fine surface finishes.

- Flagship cylindrical grinding with maximum performance and flexibility: The STUDER S41 features dozens of wheelhead configurations that sit atop the Granitan base with integrated coolant channels. Together, these options provide a range of production, measuring, gaging and dressing capabilities while delivering peak performance thanks to the thermal stability and vibration damping characteristics of the Granitan base.

- A compact universal grinder: The small but mighty STUDER S23 universal cylindrical grinding machine offers high quality grinding technology that’s ideal for small- to medium-sized workpieces. Especially suited for moldmaking and toolmaking for the automotive, aerospace and medical technology industries, the unit is capable of producing complex geometries both in single-part and series production.

Sharpening the Future of Toolmaking

When it comes to cutting tools, there are no complex geometries or advanced materials that WALTER can’t handle. WALTER tool grinding technology, accompanied by the robust HELITRONIC TOOL STUDIO software, transforms challenging jobs into uncomplicated and straightforward work. The following tool grinding machines and systems are designed with efficiency in mind:

- Entry-level for one setup: The HELITRONIC RAPID machine produces and regrinds rotationally symmetrical tools with small and medium diameters in a single setup. It offers machining of HSS, carbide, cermet and ceramics, an optional top loader for automated loading and an optional torque motor on the A-axis.

- Flexible and configurable grinding: The HELITRONIC MINI PLUS machine with the Laser Contour Check option is suited for small and medium diameters.

- Tool erosion and grinding with built-in fire safety: With the new Fire Stop & Go function, the HELITRONIC RAPTOR DIAMOND machine immediately shuts down the cause of the fire before activation of the extinguishing system. In the event of deflagration, the function enables automatic analysis and continuation of the process.

- High precision laser machine designed for brazed diamond tools: Enabling machining of PCD tools at up to twice the speed of wire EDM, the VISION LASER with Robot Loader 25 offers complex 3D geometries in a single setup. Operation is intuitive, sustainable and future-proof with the system’s C.O.R.E. panel with GTR ProfDia laser software.

- Measuring machine: HELICHECK PLUS is for both micro-tools and standard tools.

- High precision measuring for micro and nano tools: the HELICHECK NANO machine features two high resolution cameras (up to 400x magnification), newly developed hydro-expension system for maximum concentricity, fully automated measuring sequences with C.O.R.E. integration and OPC UA (Open Platform Communication Unified Architecture, used worldwide) interface for smart manufacturing.

The Ultimate Time Saver

When it comes to multi-tasking operations for surface and profile grinding operations, BLOHM and MÄGERLE five-axis multi-tasking production cells that are capable of milling, drilling, probing and grinding in a single setup.

The BLOHM MC7, the latest edition to the BLOHM line, is equipped with a large tool magazine and an ultra-rigid base. This machine excels at machining complex workpieces and difficult-to-machine materials that are typically found in aerospace applications. This machine also features an overhead dresser, enabling continuous dress creep feed (CDCF) grinding processes.

MÄGERLE showcased the MFP 30 that also performs the same multi-tasking machining as the MC7 but is ideal for complex geometries where lighter amounts of material need to be removed. It is especially useful for machining guide and rotor blades as well as heat shields for aircraft turbines.

Find new solutions!

Looking for more information about one or more of the innovations mentioned above? Locate the “Products and Services” tab at the top of this page for links to further details of UNITED GRINDING technologies that will improve your company’s grinding know-how, confidence and profitability.