The reasonably priced

for individual requirements.

Basic Data

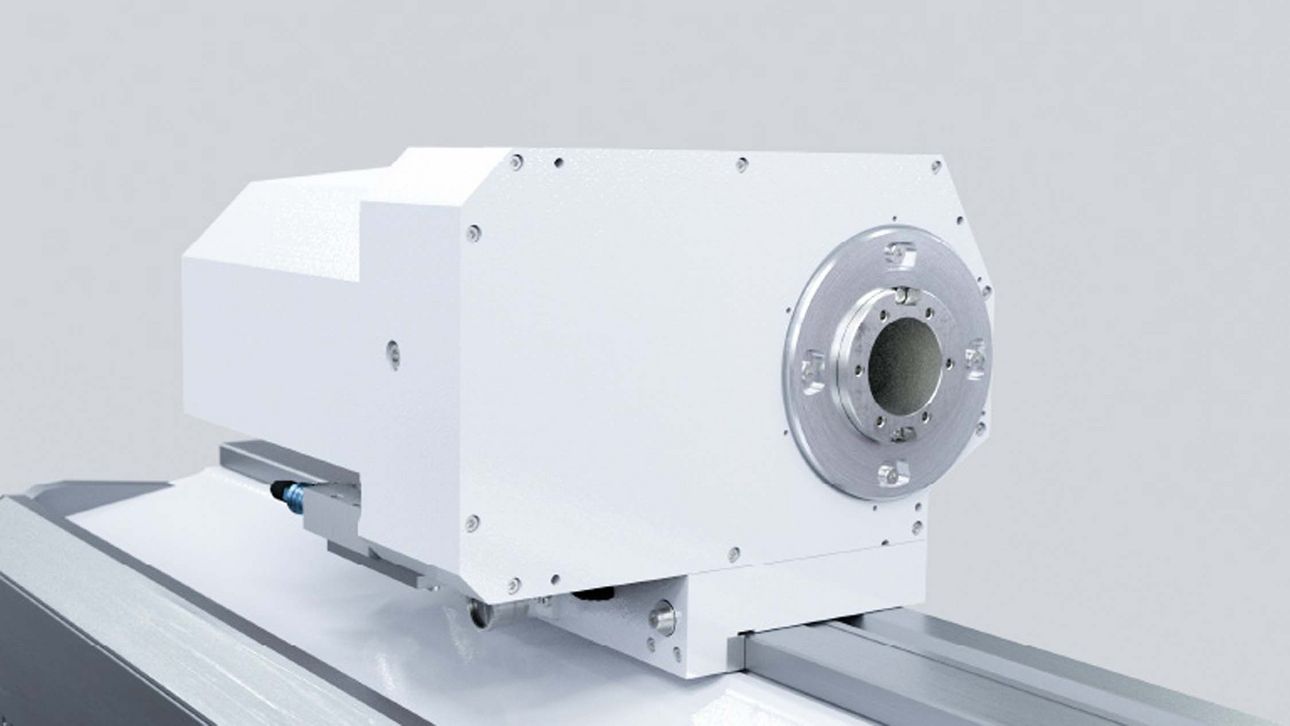

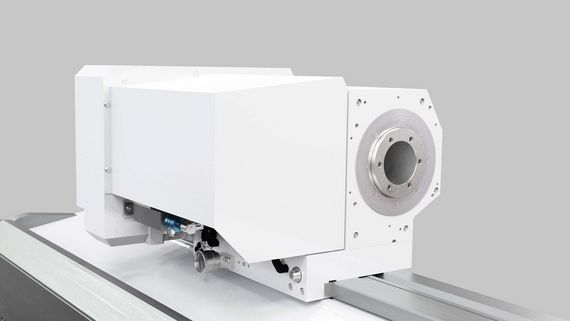

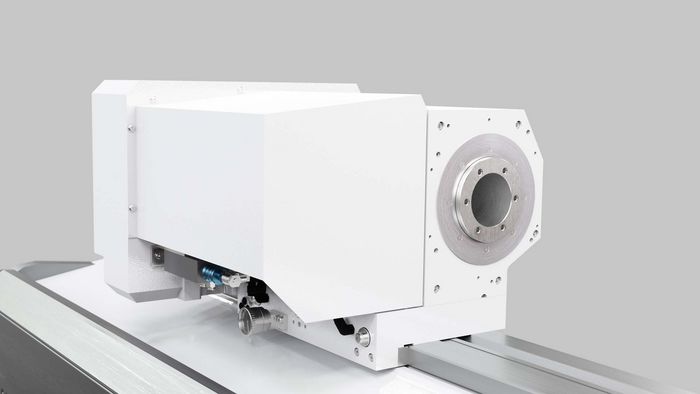

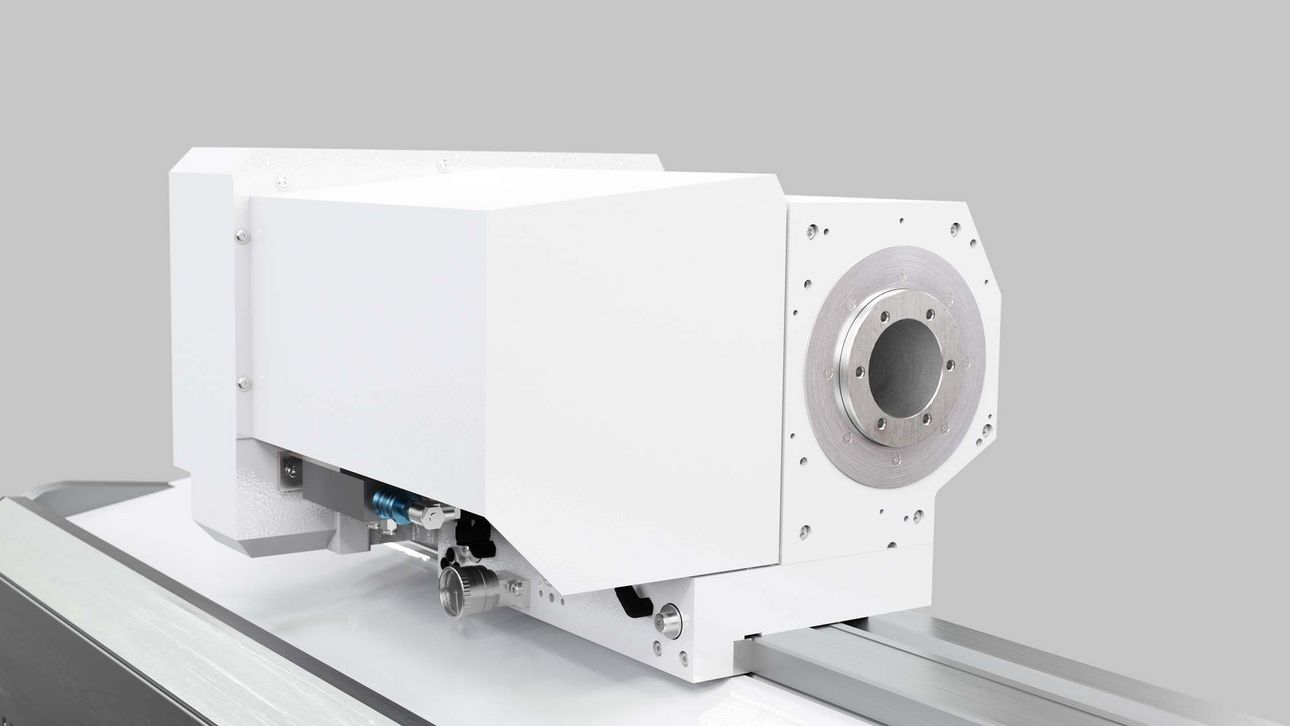

The S33 is a CNC universal cylindrical grinding machine for the individual and batch production of medium-sized workpieces. It has a distance between centres of 400mm (15.7") / 650mm (25.6") / 1,000mm (40") / 1,600mm (63") and a centre height of 175mm (6.9"). It can machine workpieces with a maximum weight of 150kg (330lbs).

Changing over from grinding between centres to live spindle grinding is particularly easy on this machine. The new wheelhead with two motor spindles enables grinding of even more complex workpiece geometries in a single clamping. Its foundation is a machine base made of solid Granitan® S103.

Images

Hardware / Software

Hardware:

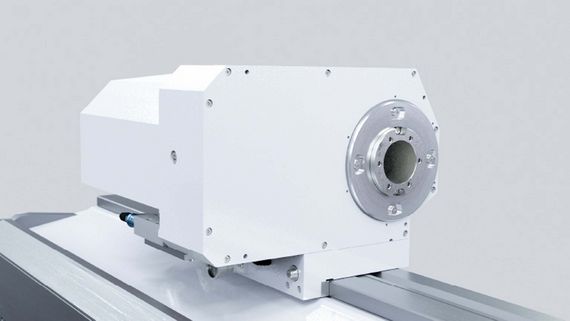

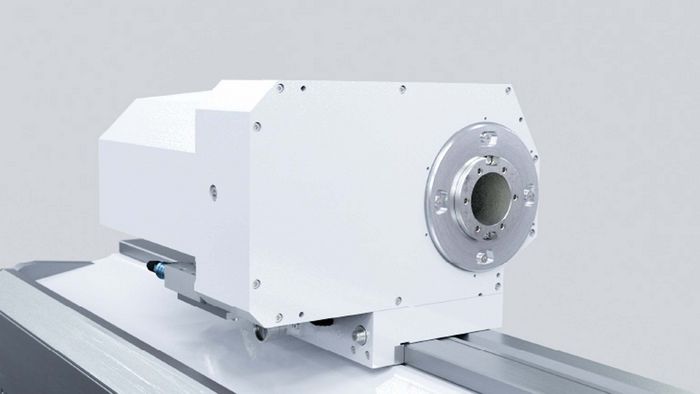

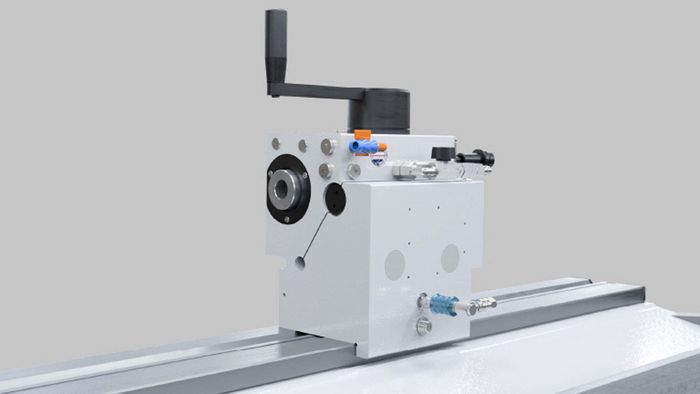

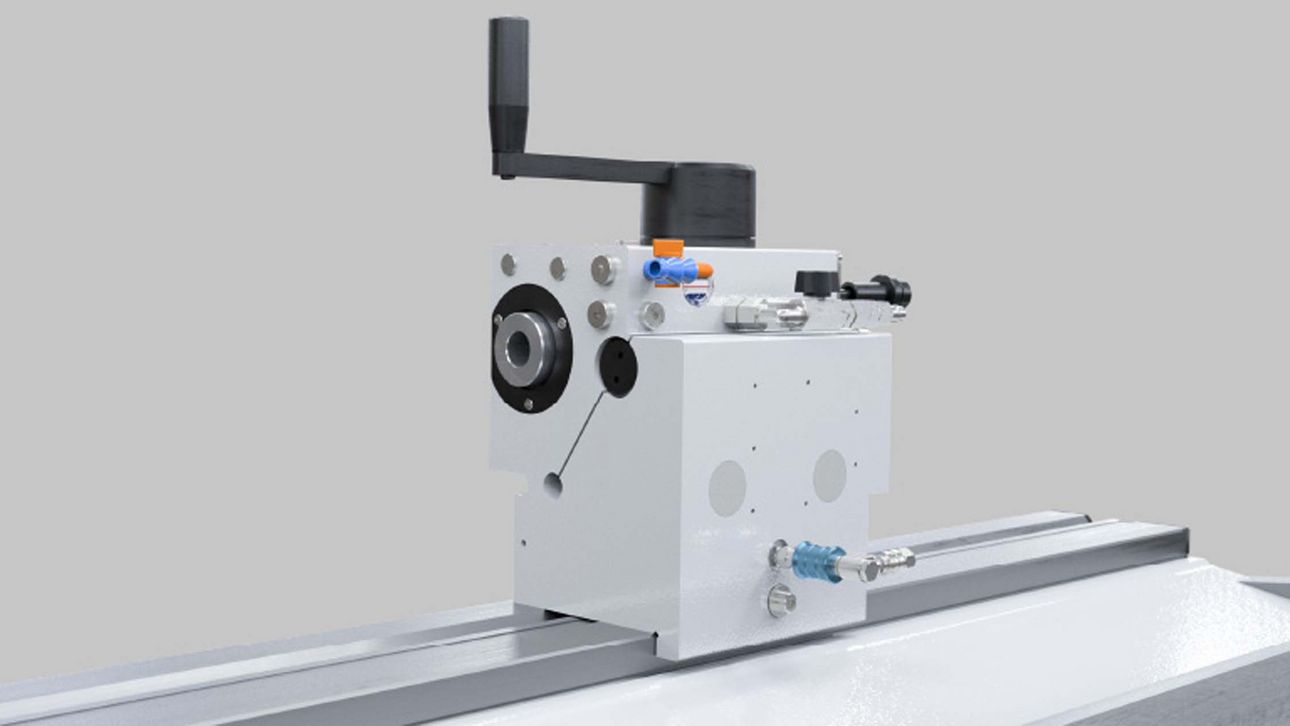

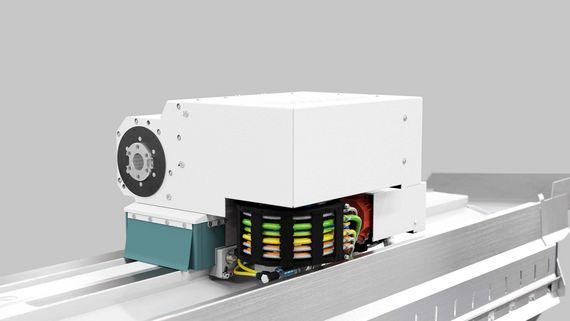

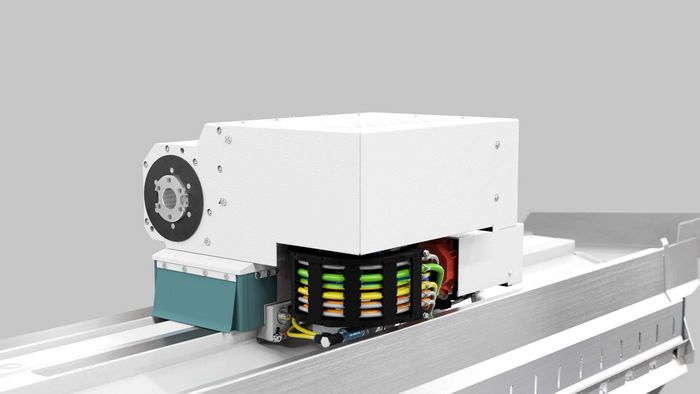

- Wheelhead versions:

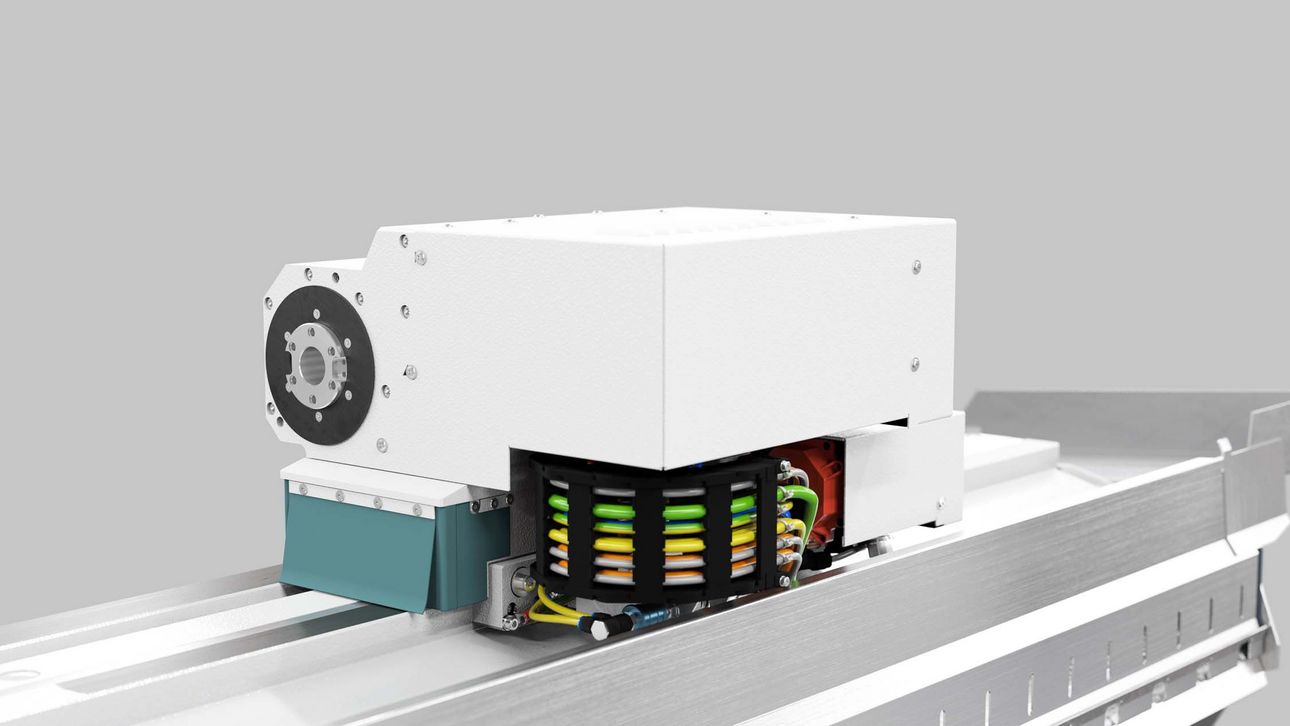

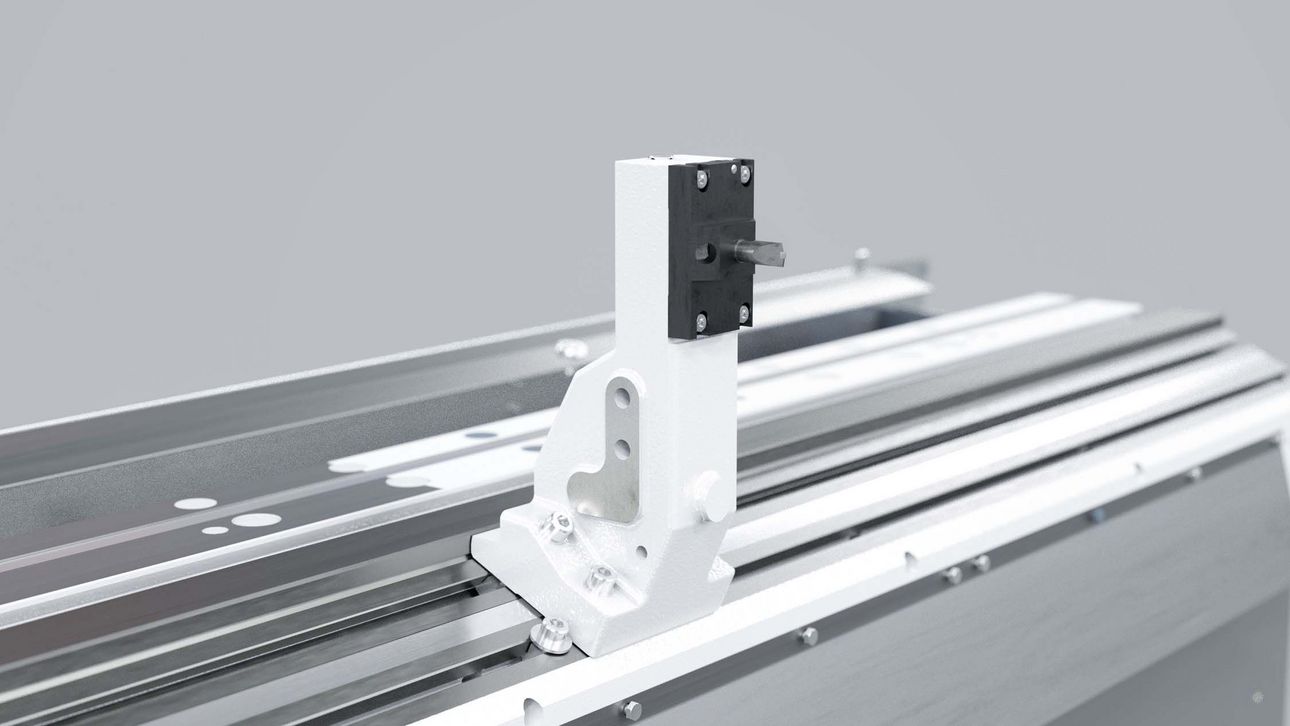

- Turret wheelhead with up to 2 external grinding spindles and 1 internal grinding spindle. Automatic swivel with 1° Hirth serration.

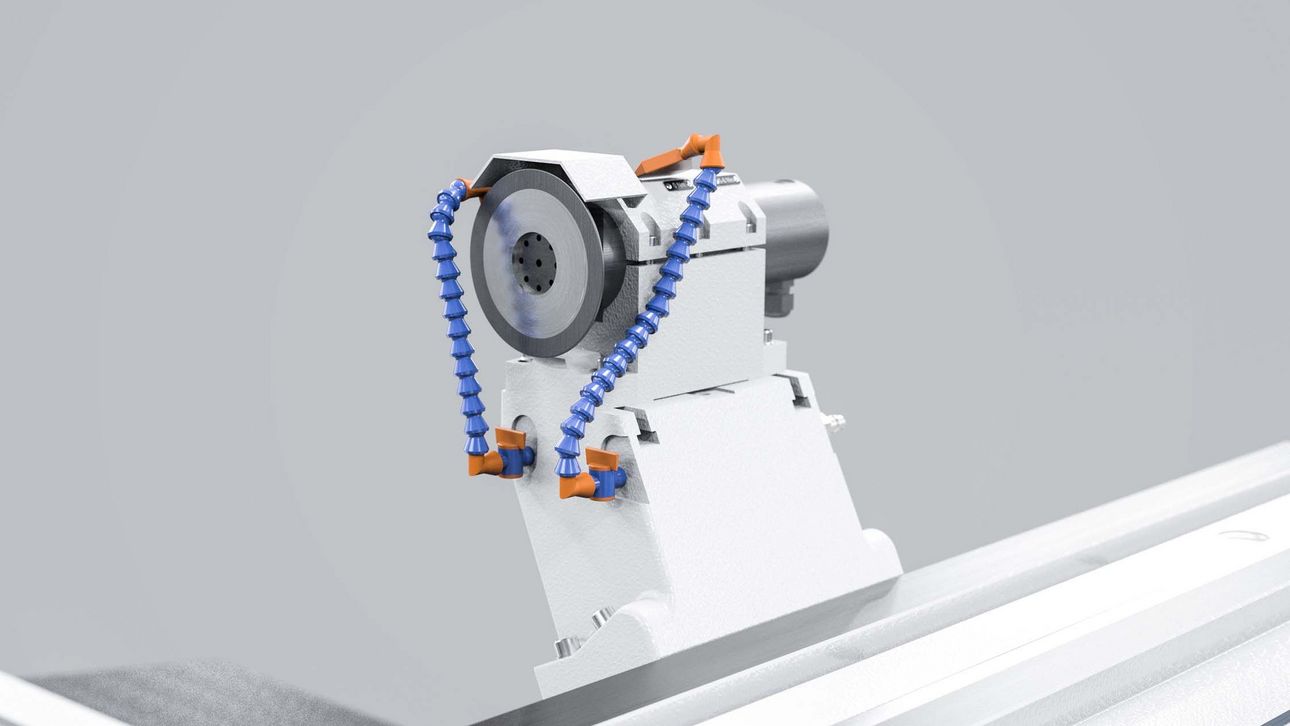

- External wheelhead with grinding wheel right, 0° / 15° / 30° - Frequency-controlled motor grinding spindles for external and internal grinding

- C-axis for the workhead, enabling form and thread grinding

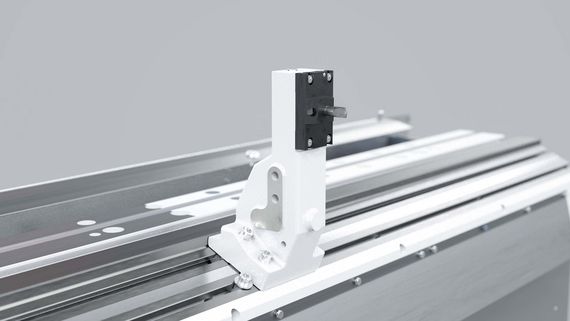

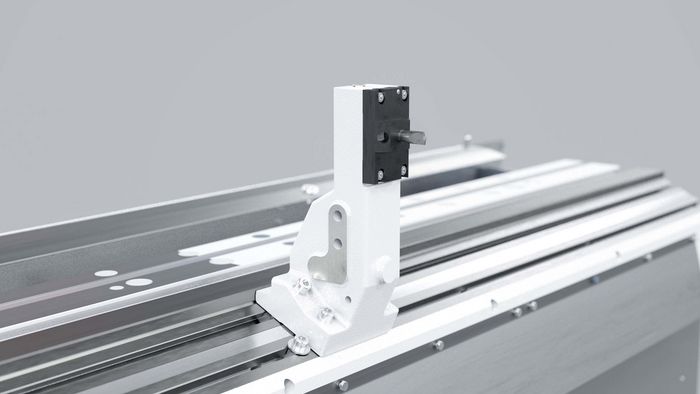

- Worktable with integrated double T-slot for dressing devices

- C.O.R.E. Panel

- Full enclosure with two sliding doors

- Granitan® S103 mineral-casting machine base

Software:

- C.O.R.E. OS operating system

- Extremely easy programming with StuderPictogramming

- Reduced setup and resetting times with STUDER Quick-Set

- Standardized interfaces for loader and peripheral devices

- Flexibly expandable with integrated software modules

- StuderWIN programming software (optional) for creating grinding and dressing programs on an external PC

Technical Data

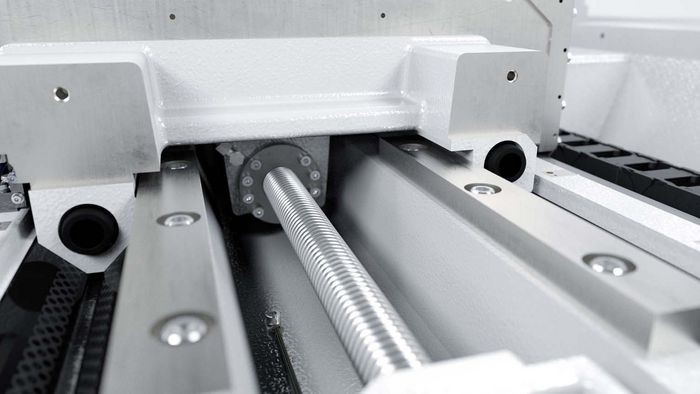

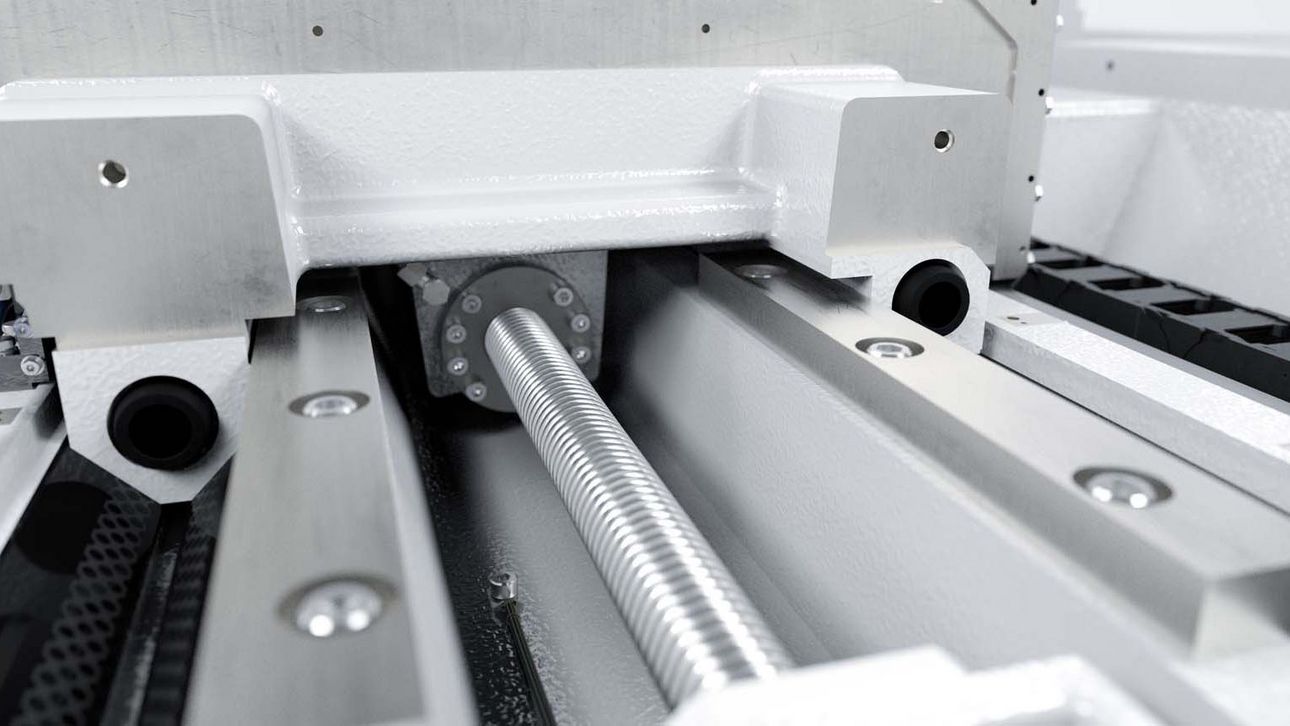

Linear Axes

Max. Travel X

370 mm

Max. Travel Speed X

15'000 mm/min

Max. Travel Z

500 mm

Max. Travel Speed Z

20'000 mm/min

Spindle drive

Max. Spindle Power

8 kW

Max. Number Of Revolutions

3'200 /min

Max. Grinding Wheel Diameter

508 mm

Max. Grinding Wheel Width

80 mm

Swiveling Axes

Swiveling Range B

255 °

Swiveling Range C

∞ °

Workpiece Data

Workpiece Length

400 mm

Workpiece Diameter

349 mm

Max. Workpiece Weight

150 kg

Distance Between Centers

400 mm

Center Height

175 mm

Linear Axes

Max. Travel X

370 mm

Max. Travel Speed X

15'000 mm/min

Max. Travel Z

800 mm

Max. Travel Speed Z

20'000 mm/min

Spindle drive

Max. Spindle Power

8 kW

Max. Number Of Revolutions

3'200 /min

Max. Grinding Wheel Diameter

508 mm

Max. Grinding Wheel Width

80 mm

Swiveling Axes

Swiveling Range B

255 °

Swiveling Range C

∞ °

Workpiece Data

Workpiece Length

650 mm

Workpiece Diameter

349 mm

Max. Workpiece Weight

150 kg

Distance Between Centers

650 mm

Center Height

175 mm

Linear Axes

Max. Travel X

370 mm

Max. Travel Speed X

15'000 mm/min

Max. Travel Z

1'150 mm

Max. Travel Speed Z

20'000 mm/min

Spindle drive

Max. Spindle Power

8 kW

Max. Number Of Revolutions

3'200 /min

Max. Grinding Wheel Diameter

508 mm

Max. Grinding Wheel Width

80 mm

Swiveling Axes

Swiveling Range B

255 °

Swiveling Range C

∞ °

Workpiece Data

Workpiece Length

1'000 mm

Workpiece Diameter

349 mm

Max. Workpiece Weight

150 kg

Distance Between Centers

1'000 mm

Center Height

175 mm

Linear Axes

Max. Travel X

370 mm

Max. Travel Speed X

15'000 mm/min

Max. Travel Z

1'750 mm

Max. Travel Speed Z

20'000 mm/min

Spindle drive

Max. Spindle Power

8 kW

Max. Number Of Revolutions

3'200 /min

Max. Grinding Wheel Diameter

508 mm

Max. Grinding Wheel Width

80 mm

Swiveling Axes

Swiveling Range B

255 °

Swiveling Range C

∞ °

Workpiece Data

Workpiece Length

1'600 mm

Workpiece Diameter

349 mm

Max. Workpiece Weight

150 kg

Distance Between Centers

1'600 mm

Center Height

175 mm