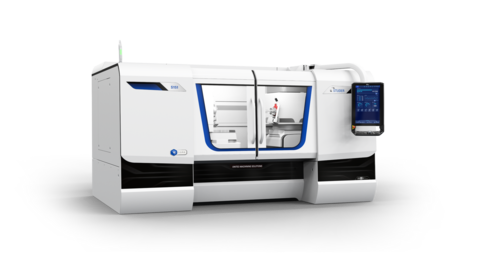

Internal Universal Grinding Applications

Bottle molds and spindle housings, neck rings and ball nuts – for parts like these, it’s the precision on the inside that counts. Manufacturers producing such parts for industries ranging from aerospace and automotive to machine manufacturing and die & mold must generate finely finished and precise ID surfaces as quickly and cost-effectively as possible.