World-Class Technology Ready for Quick Delivery

Sometimes, you need a machine and can't wait the standard lead time it takes for a custom-built machine. When you face this situation, lean on UNITED GRINDING North America's stock machine inventory to help your business meet production demands faster than ever before. Browse the list of available stock inventory, and contact us on the form below to inquire about any machine currently in inventory. This page is updated in real-time, and our inventory is subject to change at a moment's notice.

STUDER favoritCNC

The favoritCNC is a universal cylindrical grinding machine for medium-sized workpieces in individual and large series. It can machine workpieces with a maximum weight of 80kg (176lbs) / 120kg (264lbs). We have two of these machines in stock. Please complete the form below to request information about specific machine configuration.

STUDER S33

The S33 is a CNC universal cylindrical grinding machine for the individual and batch production of medium-sized workpieces. It can machine workpieces with a maximum weight of 150kg (330lbs). We have three machines in stock. Pleae complete the form below to request information about specific machine configuration.

STUDER S131r

The S131 is a radius internal cylindrical grinding machine that is especially suitable for grinding complex workpieces from very hard materials. The maximum swing diameter is 300mm (11.7") and the maximum workpiece weight is 100kg (220lbs). We have two machines in stock. Please complete the form below to request information about specific machine configuration.

STUDER favorit

The STUDER favorit is a universal CNC grinding machine capable of accommodating workpieces up to 150 kg (330 lbs). This machine is available in four sizes: 400mm, 600mm, 1,000mm, or 1,600mm between centers. We have one of these machines in stock. Please complete the form below to request information about specific machine configuration.

STUDER S110

The S110 is an internal (ID) cylindrical grinding machine for machining medium-sized workpieces. The machine has a centre height of 102mm (4") and a grinding length of max. 120mm (4.7"). We have one machine in stock. Please complete the form below to request information about specific machine configuration.

STUDER S36

The STUDER S36 is an OD production CNC grinding machine designed with larger shaft work, typical in automotive or hydraulic industries, in mind. Capable of accommodating a wheel diameter up to 610mm (24") and 125mm (4.92"), and supporting a workpiece up to 150kg (330 lbs). We have one machine in stock. Please complete the form below to request information about specific machine configuration.

BLOHM PLANOMAT HP

The PLANOMAT HP combines reproducible precision and powerful speed with high flexibility – the ideal combination for efficient profile grinding. The robust, inherently stiff design with 3-point installation ensures the exactness of the modular PLANOMAT HP machines. A driving power of up to 33 HP combined with high-precision ball screws with AC-servo guarantees high infeed speeds and accelerations. This machine is customizable to meet the needs of end user applications.

BLOHM PROFIMAT MC

The PROFIMAT MC is a highly efficient grinding centre for any application. This 36HP, 5-axis grinding machine is equipped with an HSK-80 spindle and is customizable to meet the requirements of end user applications. We have three machines in stock. Please complete the form below to request information about specific machine configuration.

BLOHM PLANOMAT XT

The BLOHM PLANOMAT XT CNC grinding machine is the ultra-precise CNC grinder for flat or profile applications requiring deep or light traverse or speed stroke grinding processes. We have six of these machines in stock in various configurations. Please complete the form below to request information about specific machine configuration.

BLOHM PROFIMAT XT

The BLOHM PROFIMAT XT CNC grinding machine is the ultra-precise, ultra-heavy duty grinder for applications where high material removal of difficult-to-machine materials is the job. We have three of these machines in stock, each with varying configurations. Please complete the form below to request information about specific machine configurations.

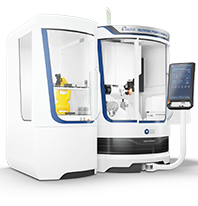

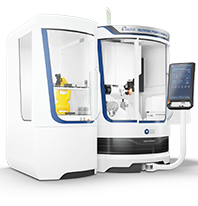

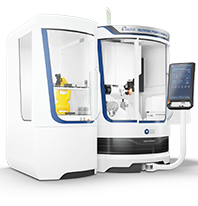

MÄGERLE MFP 30

The MÄGERLE MFP 30 is a five-axis multitasking machine capable of milling, drilling, probing, and grinding in a single clamping. This machine excels at processing workpieces with complex geometries and made from difficult-to-machine superalloys commonly found in Aerospace or Power Generation industries. We have one machine in stock. Please complete the form below to request information about specific machine configuration.

WALTER HELITRONIC VISION 400L

The HELITRONIC VISION 400 L tool grinding machine produces rotationally symmetrical tools and production parts of complex geometries in high-precision production. This machine can handle tools with a diameter of 3 to 315 mm, a tool length of up to 420 mm, and a piece weight of up to 50 kg. We have two of these machines in stock. Please complete the form below to request information about specific machine configurations.

WALTER HELICHECK PLUS

This CNC optical measuring machine offers capabilities to measure workpiece microgeometries up to 0.1 mm diameter safely and with high repeatability. We have one machine in stock. Please complete the form below to request information about specific machine configuration.

WALTER HELITRONIC MICRO

The high-precision WALTER HELITRONIC MICRO specializes in grinding complex geometries on rotationally symmetrical tools down to the smallest diameters. As an automatic 5-axis CNC machine with two additional positioning axes, high mechanical process stability and sophisticated kinematics, it excels at production and regrinding. With three motor spindles that accept up to 12 grinding wheels and an integrated robot loader, the machine redefines flexibility. We have two machines in stock. Please complete the form below to request information about specific machine configuration.

WALTER HELITRONIC POWER DIAMOND 400

The WALTER HELITRONIC POWER DIAMOND is a 2-in-1 machine designed for high production of carbide cutting tools with PCD features. The unique design offers tool grinding for carbide shafts and fluting on one spindle, and a copper rotary erosion disc in the other spindle, capable of EDM processes to provide ultra-fine finishes on superhard materials, such as PCD - all in a single clamping. We have one machine in stock. Please complete the form below to request information about specific machine configuration.

WALTER HELITRONIC G200

The WALTER HELITRONIC G200 is the perfect machine for production or regrinding of small-to-medium sized cutting tools. Taking up less than 25 sq. ft., this machine is a great addition to a manufacturer looking to insource your regrinding operation or begin production of your own cutting tools. We have two machines in stock. Please complete the form below to request information about specific machine configurations.

WALTER HELITRONIC MINI PLUS

The WALTER HELITRONIC MINI PLUS is a high production cutting tool manufacturing machine for small to medium sized tools. This machine is perfect for the cutting tool manufacturer who has high production needs and requires the world class precision and performance of WALTER grinders. We have one machine in stock. Please complete the form below to request information about specific machine configuration.

WALTER HELICHECK NANO

The WALTER HELICHECK NANO is a CNC optical measuring machine designed specifically for micro tools. Thanks to the microscopic sensor technology, this machine can accurately measure workpieces ranging in diameter from 0.1mm to 16mm. We have one machine in stock. Please complete the form below to request specific information relating to machine configurations.

flexLoad Automation Cell

The flexLoad automation cell is our standardized, fully integrated part loading system for many STUDER OD and ID grinding machines that can increase productivity by 33% over a five day period compared to human operators working alone.

versaLoad

versaLoad™ is UNITED GRINDING North America’s new entry-level standard loader, designed to deliver maximum machine-tending versatility in a compact footprint. This machine-tending automation solution delivers easy-to-use, highly flexible part-loading capabilities specially designed for high-mix, low-volume shops. Using a FANUC CRX-series collaborative robot, versaLoad™ was designed to lower the automation learning curve while delivering a solution that cooperates with lower budgets. While flexLoad™ is designed for maximum efficiency and precision at high speeds and high volumes, versaLoad™ is designed to be another member of your team as you execute smaller jobs.