Get Smart About Grinding Costly Aerospace Parts

Aerospace OEMs face some of the biggest challenges in manufacturing. To make aircraft even faster and more efficient, the parts used to build them have grown increasingly complex, both in terms of materials and geometry. Both of these factors, in turn, catapult the value of aerospace workpieces, making process security even more vital than it has ever been in the past. This is particularly true when it comes to engine turbine parts, which are often made from specially developed custom superalloys, as the raw material costs alone makes for high-value, high-risk parts that must be treated with care. And that’s why UNITED GRINDING North America works to ensure manufacturers have access to the smart machines they need for these highly complex and high cost part manufacturing operations.

By the time a turbine blade, for instance, has reached a grinding machine, it has likely already spent hours in conventional metalcutting machines. Increasingly, aerospace parts may include additively manufactured features or coatings which add further time and value. When it’s first clamped into the grinding machine, the unfinished turbine part likely already represents thousands of dollars in time, labor and material costs. If the part can’t be validated following grinding – if the measurements and material characteristics can’t be confirmed with the detailed quality control process required of aerospace manufacturers – then all that value disappears.

To address these issues, aerospace manufacturers have sought out numerous solutions. Collaborative robot technology, for example, does more than ensure perfect repeatability and reduce non-grind time – it can significantly affect machining performance. Idle machines have time to cool down, so without additional time spent warming the grinder up, it would quickly start producing out-of-tolerance parts. With effectively designed and integrated collaborative robots, manufacturers can reduce risk and increase productivity at the same time.

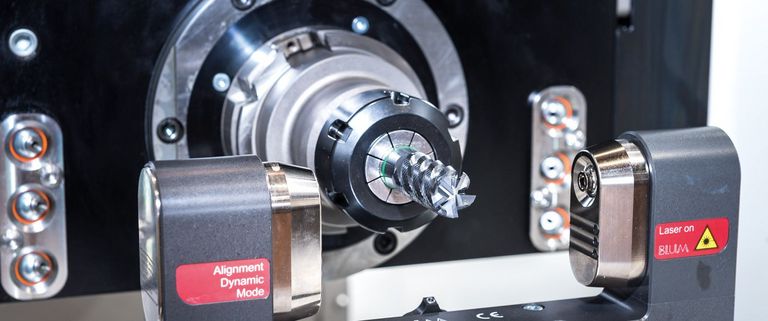

Automation extends beyond robotic loaders, however – UNITED GRINDING North America has been on the forefront of creating smarter machines capable of meeting the needs of aerospace manufacturers. Sensors transform grinding machines into smart machines, monitoring everything from coolant pressure and temperature to spindle forces and wheel diameter. Controls now feature post-processed CAD/CAM programs that give shops the power to grind more complex parts, program offline to increase machine productivity and validate programs prior to grinding to reduce risk and increase efficiency.

Of course, the real measure of a grinding process comes when the wheel contacts the material, and in aerospace shops, grinding wheels have become as advanced as the materials they grind. New abrasives and advanced cutting grains can handle the toughest superalloys far more effectively than ever before. And the process of keeping that wheel dressed is even easier thanks to advanced, fully automated dressing – for example, the MÄGERLE MFP 30 includes a space-efficient, double-sided table dresser that can accommodate numerous diamond rolls for different part profiles.

The MFP 30 also showcases how a smart grinding machine isn’t just about advanced technology, it requires a smart design as well. The machine offers complete 5-axis grinding and milling operations as well as a direct-drive, 12,000 rpm, 26 kW spindle to enable single-setup machining for even the most complex parts – all in a compact form factor that makes it ideal for aerospace manufacturers interested in maximizing the value of every square foot of their shops. Furthermore, its ergonomic design is well-suited for both manual and automatic part loading, making it a flexible solution that can grow with a shop’s needs.

When it comes to grinding technology, aerospace manufacturers have expectations that exceed those of their peers in other industries. They need the smartest manufacturing technology in the world – and UNITED GRINDING North America delivers it. Learn more about our aerospace technology on our industry applications page and discover how our smart technology can make your shop more productive, even when it comes to the world’s most complex parts.