3 Growth Industries for Shops in Surface & Profile Grinding

Profitable and successful job shops consistently look for ways to diversify their customer base and services offered. At UNITED GRINDING North America, we’ve identified three growth industries that are seeing an increased demand for precision grinding expertise.

These longstanding and emerging industries feature a variety of surface and profile grinding applications, but they all have one thing in common: they demand the right combination of manufacturing technology and know-how to get their parts made. Good news: our BLOHM and MÄGERLE machines and the UNITED GRINDING North America applications team are the winning combination for even the most challenging parts.

Let’s get started.

Growth Industry #1 for Surface and Profile Grinding: Hydraulics

Much of the activity that the UNITED GRINDING North America team sees in the hydraulics industry today pertains to gerotor pumps. Thanks to their consistent performance, low noise during operation and low maintenance requirements, gerotor pumps are used in a wide variety of industrial and automotive applications, including oil and fuel pumps, hydraulic motors and power steering systems.

The manufacturing of gerotor pump parts is not like traditional cylindrical grinding projects where ID and OD are each ground in a single part. Rather, they require grinding a star feature on ID and OD and creating two entirely separate parts that come together. After assembly, the pieces work as a team to pump fluids. In the inner rotor, a standard size grinding wheel of 16” or 20” starting diameter is used. For the outer rotor, a small wheel is used to generate the profile.

Surface and Profile Machine Recommendation for the Hydraulics Industry

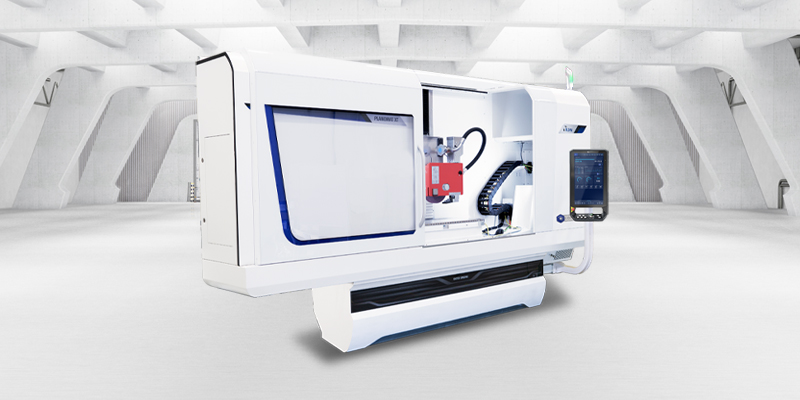

And speaking of equipment, the UNITED GRINDING platform you should examine for this hydraulics work is undoubtedly the BLOHM PLANOMAT XT. It’s the most proven creep feed grinder we have, and the flexibility it offers for a huge range of applications is unmatched.

Remember, if any tolerances in these hydraulic parts are slightly out, the pump wears out quicker—and it’s ridiculously loud before it does. These parts need to be made precisely every time.

We have one customer that had to coat their parts with Teflon to reduce noise. But with the precision and repeatability of the PLANOMAT XT, that costly and environmentally-unfriendly step is no longer needed.

Growth Industry #2 for Surface and Profile Grinding: Semiconductors

In late 2022, the CHIPS and Science Act was signed into law to help boost domestic semiconductor manufacturing capacity, innovation and competitiveness. At UNITED GRINDING North America, we are officially doing our part to help on-shore the grinding of silicon carbide (SiC) for chip manufacturing.

Grinding raw SiC boules into finished pucks has been a labor-intensive process that demands high precision, and our surface and profile machines are a great fit for the work that needs to be done. The process takes crystal ingots that are anywhere between 6 to 10 inches in diameter and 1 to 4 inches high, then grinds the faces parallel to the crystal plane in order to find the crystal in each structure.

In a nutshell, you take the ingot, X-ray it to find the crystal plane, feed that data into the machine, index the part to the direct plane, then grind flat to that crystal plane. As you may have guessed, it takes a highly precise machine to be able to do this consistently. UNITED GRINDING has them.

Surface and Profile Machine Recommendation for the Semiconductor Industry

You have a couple great options here. First is the MÄGERLE MFP 30, a 5-axis surface and profile grinder with tool changer and wheel changer capabilities. Next is the BLOHM PROFIMAT MC, a 5-axis machine without the tool changing capabilities. The ideal machine for your shop depends on your unique application.

This is a good time to mention part of what sets UNITED GRINDING equipment apart: the people who support it at UNITED GRINDING North America. Both before and after your purchase, we always keep your specific requirements in mind to give you a machine and a roadmap that help you meet those requirements day in and day out.

Growth Industry #3 for Surface and Profile Grinding: Woodworking and Plastics

In woodworking, the application surface and profile grinders typically tackle is the production of wood chipper blades. And in plastics, you’re looking at something similar: parts that very much resemble wood chipper blades, but they chop plastic rather than wood.

Chipper blades are made of hardened tool steels with formed surfaces that aid the chipping process and tool assembly. Given the difficult to machine materials and forms, creep feed grinding is the optimal process to produce and regrind these blades.

Companies typically turn to UNITED GRINDING because the metal removal rates of their current machines can’t keep up with customer demand. A couple solutions in the BLOHM and MÄGERLE family boost those MRRs in a hurry.

Surface and Profile Machine Recommendation for the Woodworking and Plastics Industry

For surface and profile grinding, you can’t go wrong with either the BLOHM PROFIMAT, BLOHM PLANOMAT or MÄGERLE MFP platforms for woodworking and plastics work. Our creep feed griding process can reduce blade cycle times by as much at 75% over conventional surface grinding, and our machines deliver burr-free form grinding for blade lengths up to 100”.

Say the word and we’re happy to perform test grinds to demonstrate the higher MRR you’re looking for.

Ready to Strengthen Your Industry Presence? Talk To Us.

All of us at UNITED GRINDING North America are here to help you achieve lasting success. That means finding out all that we can about your present and future applications to set you up with the best surface or profile grinding machine for the job. On top of that, we equip you and your team with comprehensive training and reliable Customer Care to ensure your machine works hard on your floor for years—and even decades. Talk to us when you’re ready for that business-boosting conversation.

![[Translate to English:]](https://cdn.grinding.com/typo3temp/assets/_processed_/2/6/csm_529c2221ca6707c35b129a4ccfcc21c1a4f39d99-fp-320-180-0-0_2466d0bbcb.jpg)

![[Translate to English:]](https://cdn.grinding.com/typo3temp/assets/_processed_/2/6/csm_529c2221ca6707c35b129a4ccfcc21c1a4f39d99-fp-320-180-0-0_4a588b9abc.jpg)

![[Translate to English:]](https://cdn.grinding.com/typo3temp/assets/_processed_/8/a/csm_529c2221ca6707c35b129a4ccfcc21c1a4f39d99-fp-768-320-0-0_dee53008b4.jpg)

![[Translate to English:]](https://cdn.grinding.com/typo3temp/assets/_processed_/8/a/csm_529c2221ca6707c35b129a4ccfcc21c1a4f39d99-fp-768-320-0-0_1352bc4696.jpg)

![[Translate to English:]](https://cdn.grinding.com/typo3temp/focuscrop/529c2221ca6707c35b129a4ccfcc21c1a4f39d99-fp-1280-420-0-0.jpg)

![[Translate to English:]](https://cdn.grinding.com/typo3temp/focuscrop/529c2221ca6707c35b129a4ccfcc21c1a4f39d99-fp-1500-500-0-0.jpg)