3 Advantages of Using WALTER Machines for Medical CNC Machining

The WALTER line of HELITRONIC tool grinders has gotten to a point where they might need no introduction. But because we love talking about them, we’ll provide one anyway: with a complete range from general purpose tool grinding machines to micro tool grinders—all of which answer complexity with accuracy—they’re a surefire way to boost the precision and profitability of your business.

That top-to-bottom precision is especially useful in the medical industry, where small parts like medical tools, cutting tools and bone pins and larger parts like knee or hip replacements all reside. No matter what medical part you’re machining, there’s probably a WALTER machine for it.

Advantage #1: the HELITRONIC and HELICHECK one-two punch

For cutting tools, bone pins and other small medical parts, take a look at the HELITRONIC HELITRONIC MINI PLUS. This machine excels with small to medium diameters (up to 20 mm). Be sure to pair the machine with automation if you want to be floored by the production capability.

Shops producing larger parts like knees, hips and other longer pieces would do well to examine the HELITRONIC POWER 400 L. This linear drive machine is ideal for the high precision production of parts with complex geometries.

Meanwhile, the HELICHECK line of inspection equipment takes care of pain points the medical industry often has. The HELICHECK PLUS optically scans 3D imaging of medical parts, easily verifying the work you’re producing and doing it in less time.

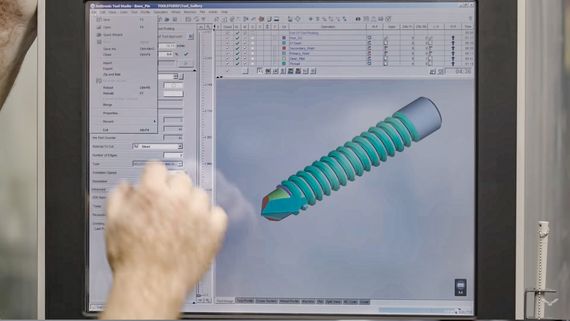

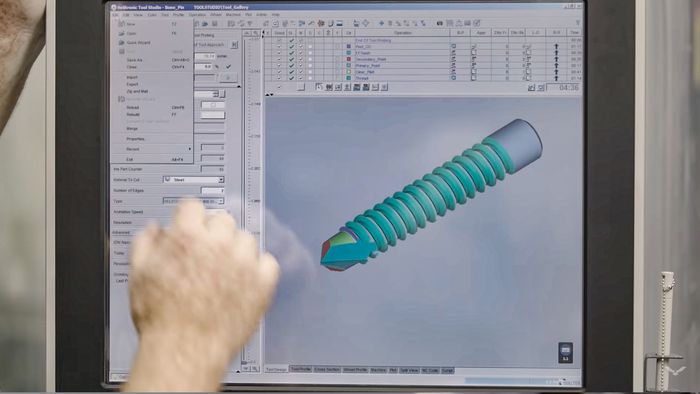

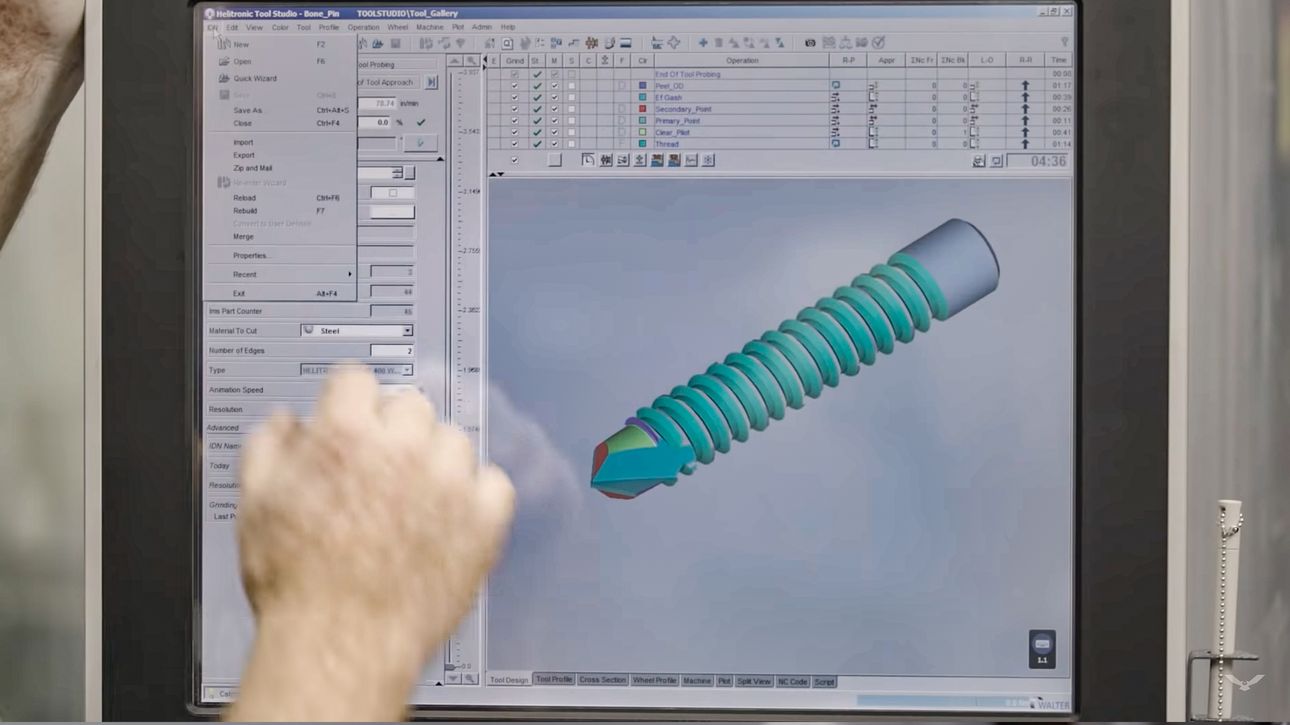

Advantage #2: HELIOTRONIC TOOL STUDIO software

WALTER’s popular software simplifies the design and grinding of bone pins, bone screws, skull drills, bone reamers, and whatever other tools you need to produce.

Design, programming, simulation, and production are all handled by this powerful conversational software. And thanks to the interplay between the HELIOTRONC TOOL STUDIO software and HELIOTRONIC CNC control, it’s easier than ever to grind complex medical tools in a single clamping.

Advantage #3: the 6-axis FANUC robot

Talk to a WALTER customer and they’re likely to tell you what they think is the biggest advantage: no one competes with the UNITED GRINDING robot.

If flexibility is what you’re after, you’ll be thrilled with the FANUC robot that can be paired with WALTER equipment. There are many different setups ready to be used, including on knees where the body replacement part is loaded on an HSK arbor and then loaded into the machine.

For drills, we use a cylindrical loader where it moves them from pallet to collet. The robot loader teaches itself, which means you don’t have much setup time. You can have four different shelves inside the robot, which can yield up to 500 parts per pallet for small diameters. That’s a whole lot of tools.

Overall, the robot is incredibly easy to use. Typically, when you have something easy to use, you sacrifice flexibility. But we’ve merged the two so you can quickly do many types of parts and tools.

Ready to produce world-class medical tools and parts? Time to talk to WALTER.

The entire WALTER lineup contains perks and advantages we didn’t list here. It’s a truly special machine family, and that claim quickly cements itself as fact after you’ve spent a bit of time with your tool grinder.

Reach out any time to talk about your application and get it paired with the ideal WALTER tool grinder. It’ll be one of the best moves you make this year.

Header image source: Grinding Bone Pins from Titans of CNC