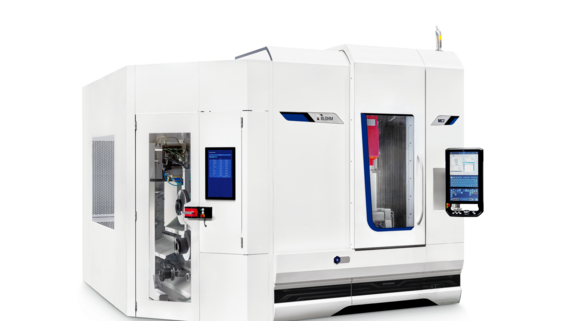

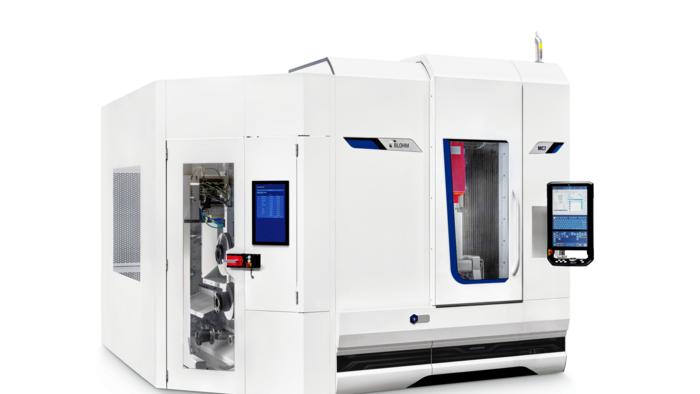

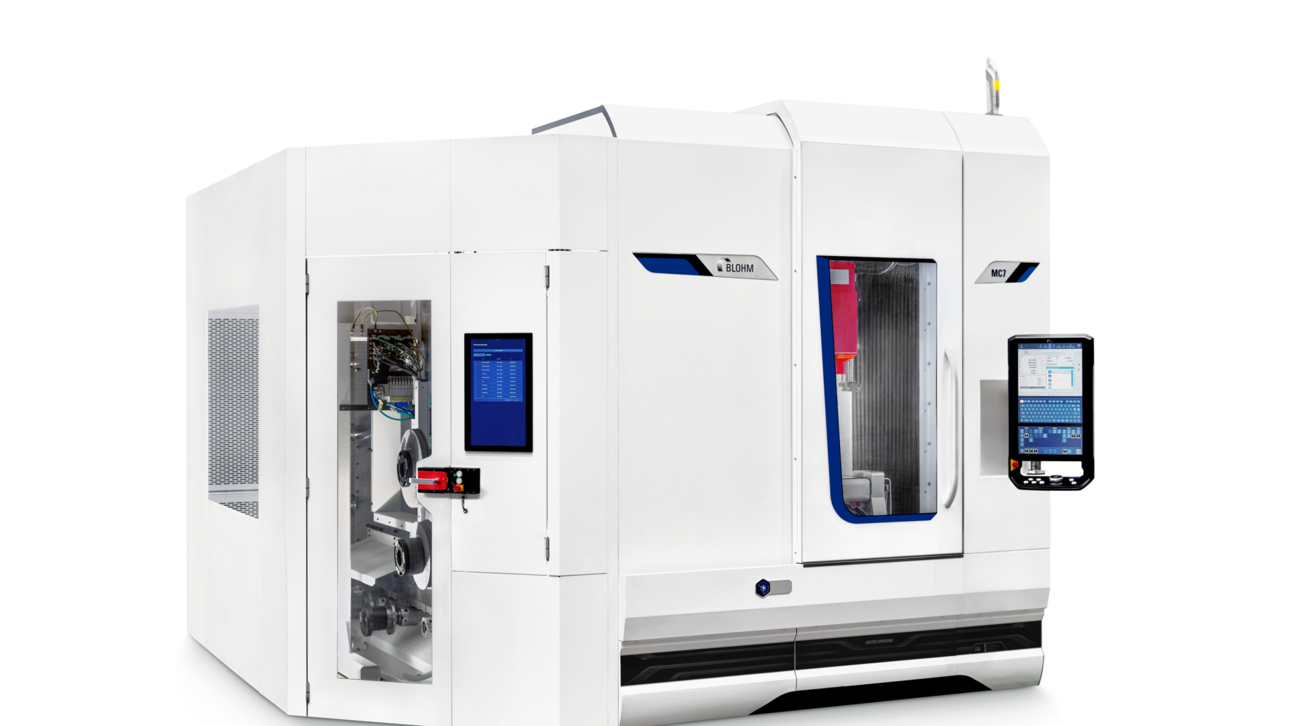

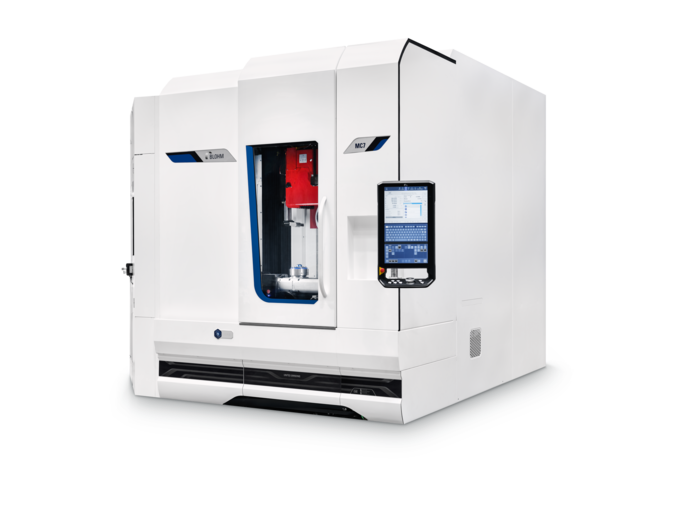

BLOHM has specially designed the MC7 for those markets where multi-face machining of complex workpieces in just a single clamping operation is demanded. The high-performance spindle, which allows speeds of up to 12,000 rpm, and the large working area make the grinding center ideal for applications such as turbine vanes and blades are for use in the aviation and energy industry.

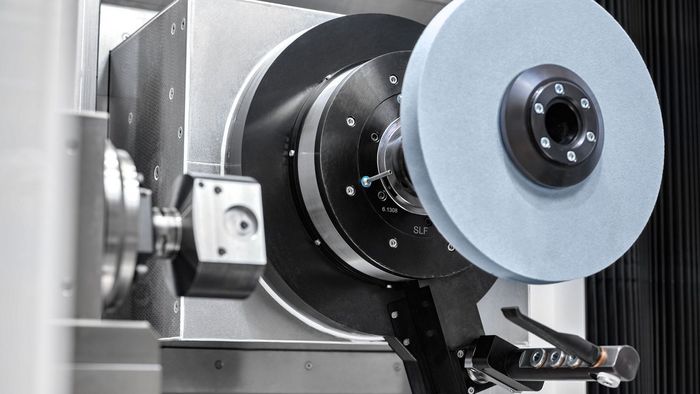

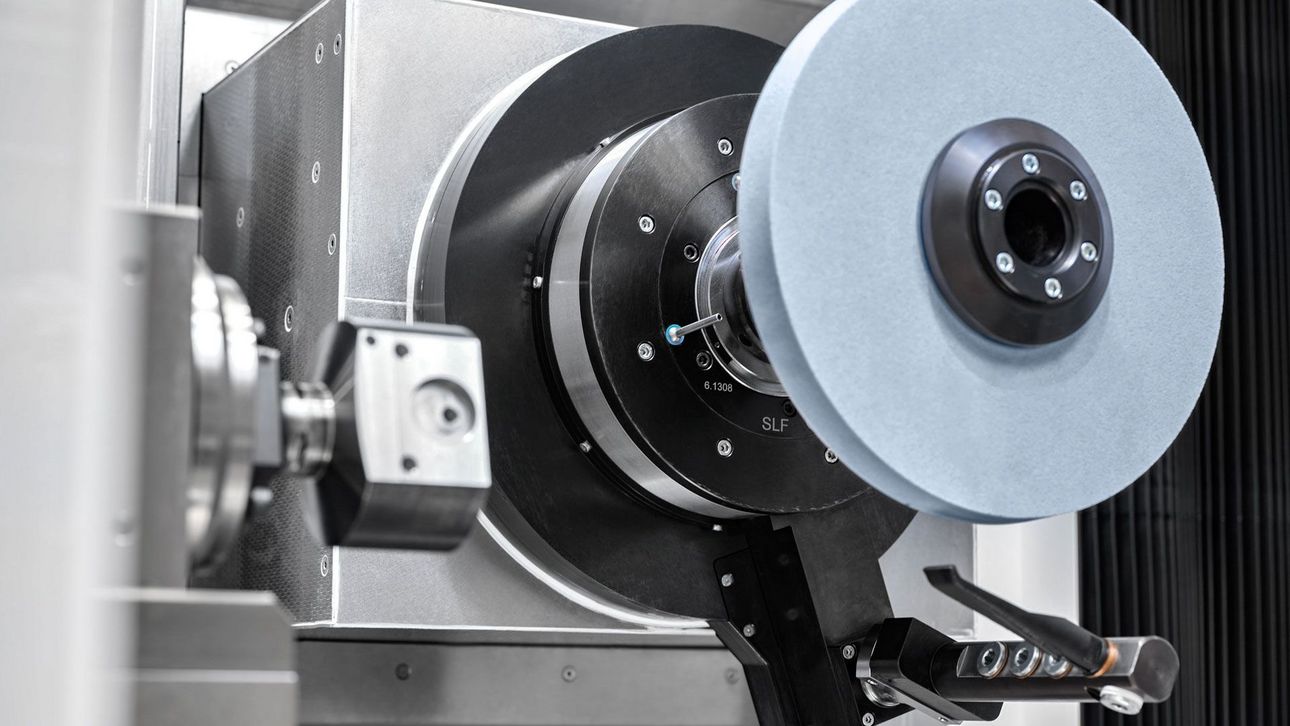

The P360 coolant nozzle technology combined with various axis combinations allows to create new opportunities in grinding of complex geometries. The optional Tool changer ensures less operator intervention, and the continuous dressing process enables high material removal rates with high profile accuracy over long cuts. Several options for coolant supply will guarantee highest results in quality and productivity.

The machine can be loaded from the front, the top and from the side to run all kinds of automated processes.

Hardware:

- Modular machine concept

- P360 coolant nozzle

- Grinding wheel size up to 500mm

- Tool changer with 72 positions for tools and grinding wheel diameter up to 400mm

- Spindle power: 27,5 / 62 kW

- Spindle speeds up to 12‘000 min-1

- 5-axis system

- Grinding, milling and drilling capability

- Table and overhead dressing solutions

- C.O.R.E. panel

Software:

- Pre-programmed grinding and dressing cycles

- Intuitive operation

- Focus on work and production safety

- CAD/CAM connection

- C.O.R.E. OS operating system