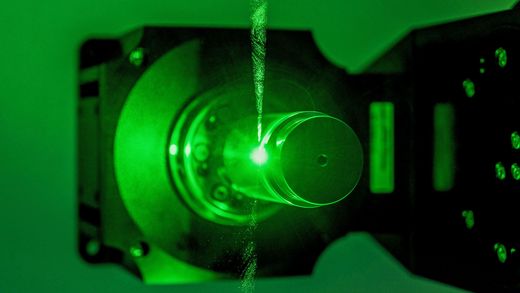

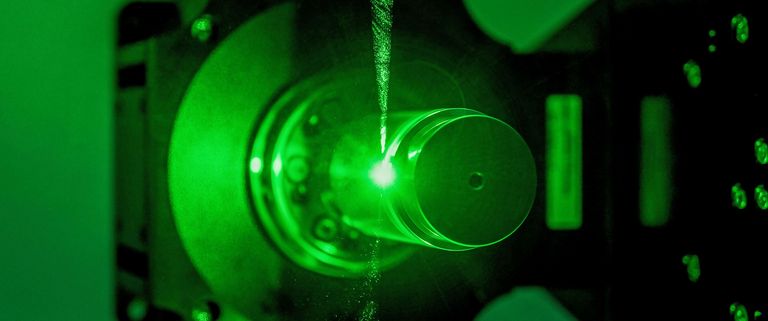

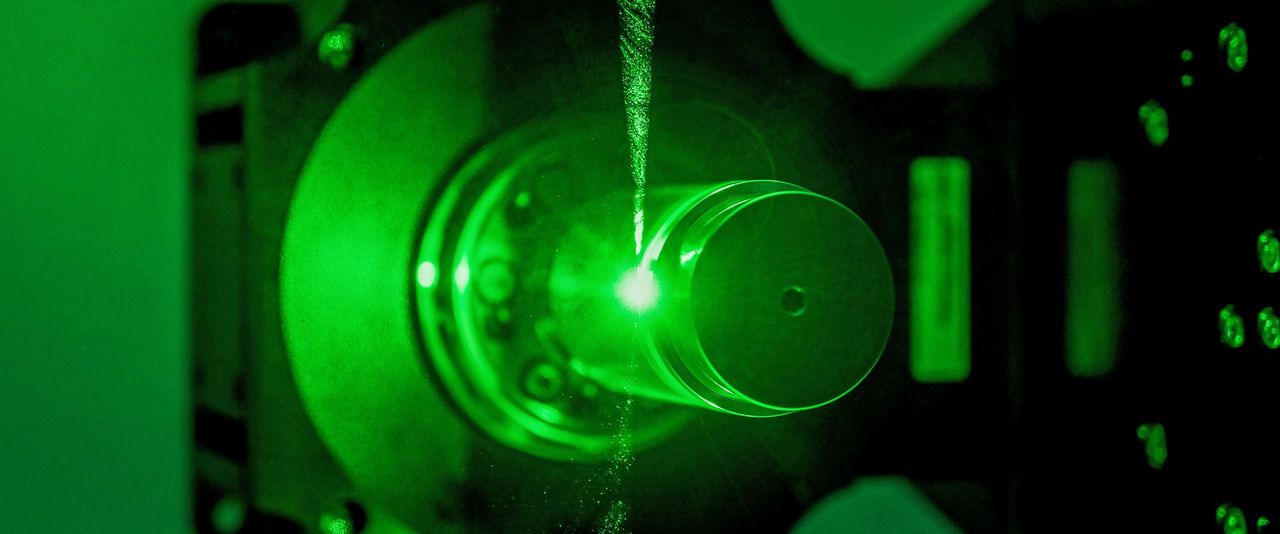

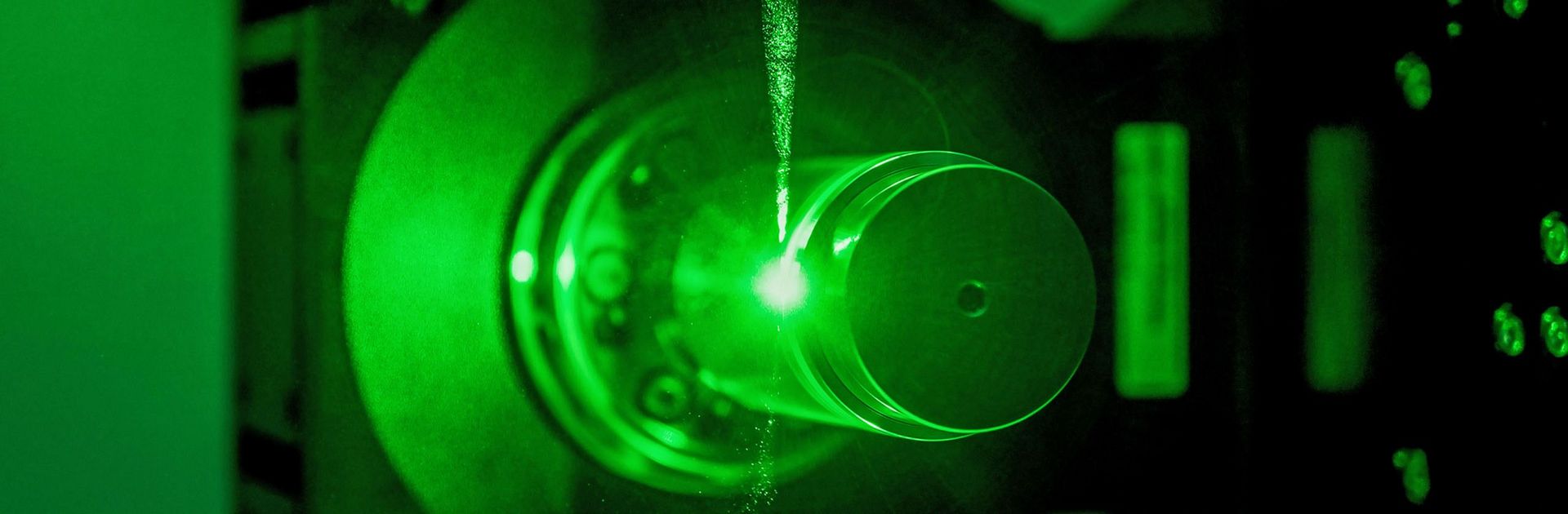

Tool Laser Ablation Applications

Diamond cutting tools include a wide range of materials – including cubic boron nitride (CBN), polycrystalline/monocrystalline diamond (PCD/MCD) and chemical vapor deposition diamond (CVD-D) – and all of them pose tough machining challenges. To efficiently process these materials and keep up with demand, manufacturers supplying diamond cutting tools to the metalcutting industry, as well as cermet, ceramic and hard metal components of all kinds, are increasingly turning to laser ablation to handle material removal and to generate the finest surface finishes possible.