Checking In On the First Class of the UNITED GRINDING North America Apprenticeship Program

In August 2023, UNITED GRINDING North America launched its Apprenticeship Program. Conducted in collaboration with Sinclair Community College in Dayton, Ohio, the apprenticeship promised a two birds, one stone approach: classroom education with an Associate’s degree, plus on-the-shop-floor employment with a world-class CNC grinding manufacturer—with fair compensation attached.

The program has thrived. Anchored by Apprenticeship Coordinator Andreas Brockmann (a man with a wealth of training and education experience), tangible progress is clear after just two years. Of the four signees in 2023, three are still with UNITED GRINDING North America with their Associate’s degrees in-hand.

On top of that, in the Fall of 2024, the U.S. Department of Labor Recognized UNITED GRINDING North America as an Apprenticeship Ambassador.

It’s been a mutually beneficial endeavor. While our apprentices have received an education, job training and compensation, all of us at UNITED GRINDING North America have benefitted from their hard work, reliability and energy.

The new flow of the apprenticeship

With the Associate’s degree obtained, apprentices will have more availability for on-the-job tasks. With that added time comes a unique aspect of the Apprenticeship Program: letting them work across multiple departments and disciplines at UNITED GRINDING North America. “We rotate them through Sales, Marketing, Warehousing, Production, Field Service. They’ll be learning from all these departments over the next two years,” Brockmann said.

“When they’re done, they’ll have training no one can take away from them. We hope they’ll stay with us, but regardless, they’ll have knowledge and skill that very few recent graduates will have. It’s a boon to the manufacturing industry as a whole.”

Looking ahead to graduation

Brockmann has been doing this work for decades, and his favorite part of the job hasn’t changed: it’s always been graduation day.

“The ceremony is nice, but what’s really memorable is talking with the kids and their parents afterward,” he said. “You get the sense that this truly changed lives.”

“Now at UNITED GRINDING North America, we change lives while we change our culture. Working here, seeing the new faces, it’s the future of the company. It extends us into the future and revitalizes us.”

Checking in with the three apprentices

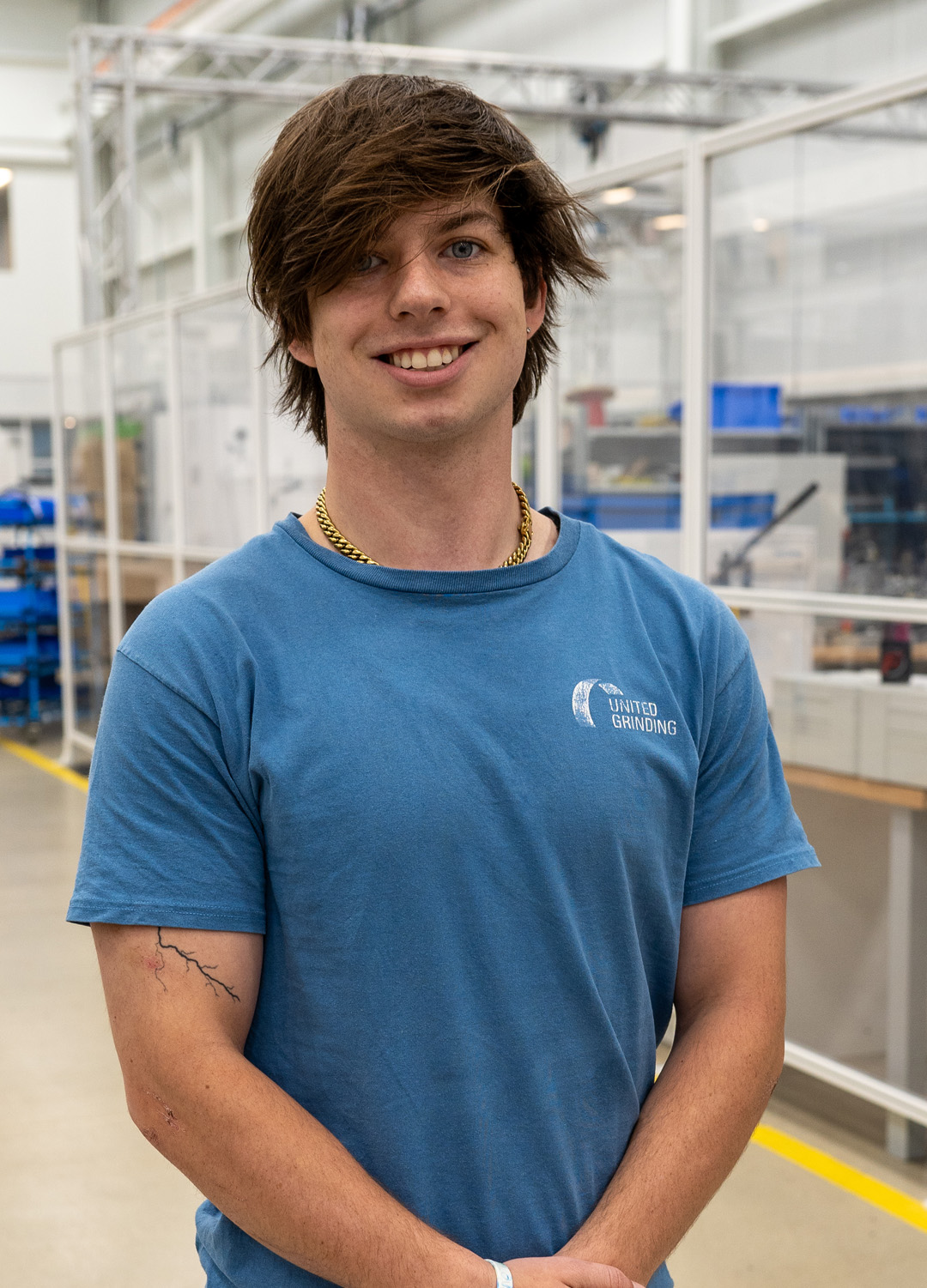

Now that Nick Hoffman, Owen Johantges and Trent Saylor are halfway through their 4-year apprenticeship, we wanted to check in with them on the things they’ve learned thus far.

Why did you decide to pursue the apprenticeship?

Nick: I wanted to get a college education and work on starting a career.

Owen: After I took and enjoyed digital design and CNC automation classes in high school, I decided to pursue a career in automated manufacturing.

Trent: I was looking to start my career as an apprentice after graduating from high school. I saw that the company was paying for all of the training I would be doing. Competitive pay for our age. Finally, the automation industry is advancing rapidly and will need employees until I'm out of the workforce. Overall, they treat me very well with amazing benefits.

What about the apprenticeship program has surprised you?

Nick: I didn’t expect how challenging the college courses would be.

Owen: How fast the program moves. I saw quickly that attendance is important because nobody waits for you to catch up. You gotta buckle down or risk getting left behind.

Trent: A few things. The ability to travel around the world is a great benefit. School was hard. The plant is surprisingly clean and well-maintained.

What were some of the biggest challenges you’ve faced?

Nick: Learning to use the machines and grasping the mechanics in the shop.

Owen: I got through 3 days in a row of night classes. Had to get it done, and that meant I had to put in that work. I know this opportunity won’t come but once in my life.

Trent: School, learning machines I have never seen before, learning the operations of all shop machines, dealing with 220V and 480V AC electrical panels (I had never wired them up before).

What are some of the coolest things you’ve learned?

Nick: Learning to use CNC programming and how those machines are created.

Owen: How to run a FANUC robot, PLC programming.

Trent: Electrical circuits and components. Precision cutting tools, mill, lathe, Robodrill, and even filing. The ability to read prints, either mechanical or electrical. Being mechanically inclined since I have to use tools and know how things are done. Having to control a FANUC robot with a controller in my hand.

Any memorable projects you’ve worked on?

Nick: I enjoyed working in the machine rebuild area and helping with the creation of a dump truck.

Trent: Building an electrical panel with a vet in the field. Teardown on a machine. Running pneumatic lines with a mechanical tech vet. Mill and lathe projects, this gave me a real good understanding of both machines. 2025 capstone class.

If you could give advice to the 2023 version of yourself, what would you say?

Nick: College assignments will take a long time to complete.

Trent: The only person who is stopping you is yourself.

Learn more about the Apprenticeship Program!

It’s an incredible opportunity for engineering-minded students to get a college education while starting their careers at the same time. Get more information at the Apprenticeship Program page, then reach out to Andreas Brockmann or Amy Luther.